-

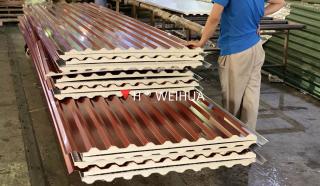

Auto stacker is a device used for finishing stacking single panels. Weihua has the auto stacker of manipulator turning-over type. It can avoid surface damage of panels from the conventional chuck type stackers. Auto stacker is one of the most important equipments for producing the high quality sandwich panels.

-

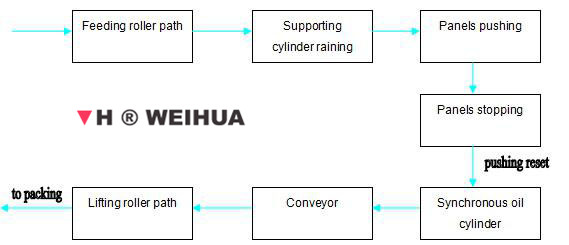

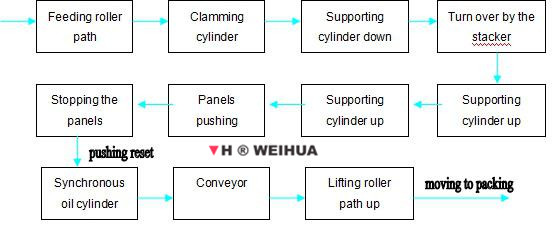

The stacker is composed by high speed moving roller path; high speed conveying stopping device, roof panel turning over device, horizontal pushing stacker and conveying rollers. Roof panel turning over device can turn the panels over 180° to save the space, so that can improve the stacker efficiency. The panels after stacking will be conveyed to the packer.

-

The characteristics of stacker: the equipment adopts pushing type and manipulator turning-over type. First, it can avoid damages from conventional chuck stacker onto the panel surface when making PU (mineral) sandwich panels with thickness of 100mm. Second, it avoids the corrugated panels flow down if the conventional chuck stacker is air leaking.

-

The stacker of the production line adopts motor-driven disc rotated device, and is safe and reliable. The lifting roller path, clamping device and turn-over roller path can keep the state of the work piece and self-locking when the electricity and air source are cut off. This is easily to regain electricity and air or handle manually in a safe and reliable way.

-

The stacker over-turning can change the speed smoothly through by adjusting the transducer. When moving to the preset position, it brake quickly and positioning correct. The turn-over roller path and the pushing device are smooth and reliable, and the panels are neatly stacked.

Automatic Stacker

Automatic Stacker