-

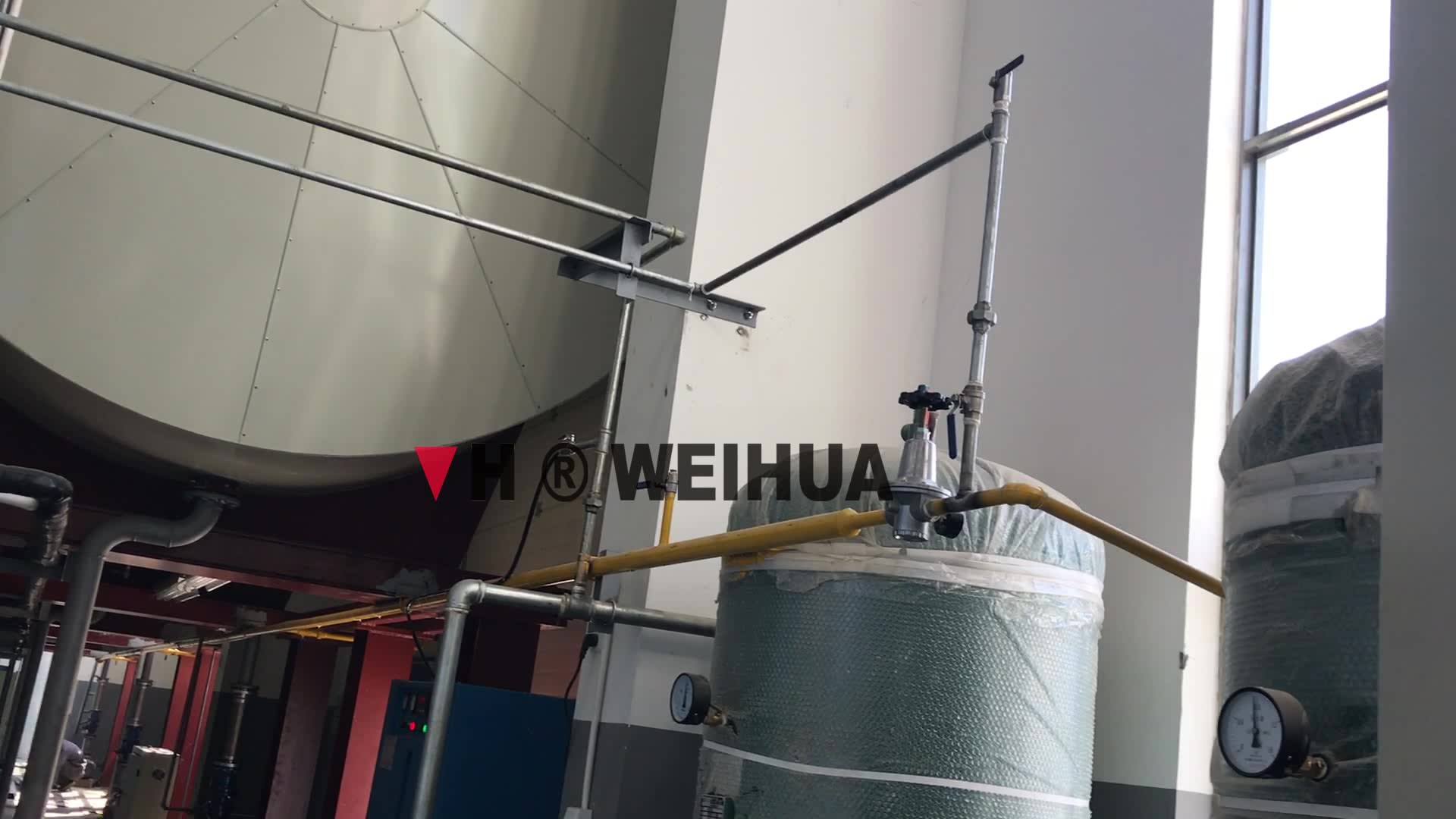

1)PU Polyol storage tank:30000L

-

2)Working volume: 30000L

-

3)Maximum working pressure: 0.3MPa

-

4)Temperature detector PT100 connected to PLC to control temperature in material tank

-

5)1 set of 3 points’ Liquid level meter

-

6)1 set of plate heat exchanger on tank backflow pipeline

-

7)Material loading pump rate of flow: 150L/min

-

8)A set of press switch to monitor and control the output pressure, and alarm

-

9)Recycle device,including the ball control valve,cycle pipe,and cooperate with the control valve to control the foaming machine for the material feeding and recycle.

-

10)Temperature control system

-

11) 1 set of pipe type heat exchanging system, 5m2

-

12)1 set of mold temperature controller to supply cold and hot water;

-

13)A set of press switch to monitor and control the output pressure, and alarm when the pressure is surpass the pre-set value

-

14)Recirculator includes 2 air control ball valves, circulating pipeline; Which assorted with air control ball valves on foaming machine to control the switchover of feeding of material and the self-recycle of the material tank

-

15)One set of heating/cooling system to control the ISO storage tank(30000L)’s temperature.

-

16)Automatic display and fault control

-

17)Option button: Manual/ Automatic operation; pump primary

-

18)Control button: control voltage, emergency stop;

-

19)Fault information will be displayed on the screen;

-

20)The electric controlling adopts Siemens PLC

-

21)Pipeline system and controlling cable

-

22)The pipeline system include inner and external pipeline. The inner pipeline is connecting the units of feeding station. The external pipeline is the feeding pipe from station foaming machine. The controlling cable is used for signal connection of the inner feeding station and foaming machine, include the parts of power line, signal line and trunking.

-

23)Coated with PU for insulation;

Concentrated Material Feed Storage System

Concentrated Material Feed Storage System