Guardrail Roll Forming Machine

Guardrail Roll Forming Machine

Guardrail Roll Forming Machine

Guardrail Roll Forming Machine

Guardrail Roll Forming Machine

TECHNICAL PARAMETER

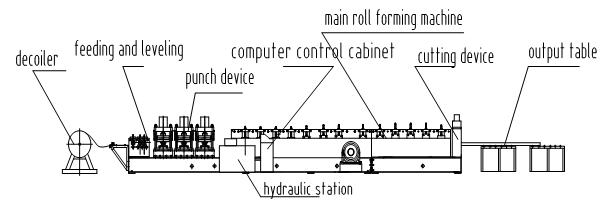

FLOW CHART

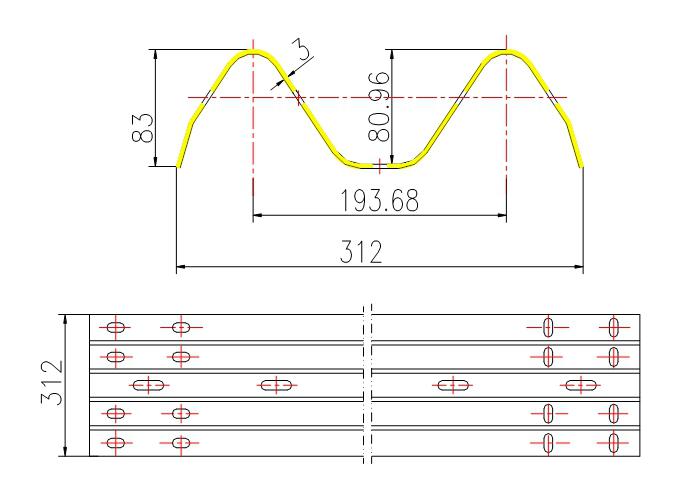

PROFILE

APPLICATION

1)Manual de-coiler:manual expanding,passive uncoil

2)De-coiler capacity: 5T

3)Machine stand: welded by steel structure, shot blast after welding, get rid of inside stress

4)guide feeding stand type:side trolley type

5)The type of feeding and straightening: two rollers for clamping and feeding, five rollers for straightening.

6)Punching type: pre-Hydraulic punching before roller forming

7)Punching die material: Cr12Mov, quenching process

8)Hydraulic pre-punching: 3 sets of punching mould

9)diameter of shaft: ¢70㎜

10)diameter of roller: ¢150㎜

11)transmission: Gearbox driven

12)motor power of forming machine:15KW×2=30KW

13)forming speed:0-10m/min

14)roll station:17 stations ( subject to the final design)

15)Material of roller: GCr15, quenching hardness is HRC58°-60°

16)heat treatment: forging--temper--anneal--normalizing--quenching—temper

17)Coil thickness: 4mm

18)Adopts hydraulic cutting

19)material of cutting blade:Cr12

20)heat treatment of cutting blade:HRC58°-60°

21)tolerance of length:10m±2mm

22)motor of hydraulic station:7.5kw

23)hydraulic oil pump:gear pump CB-E314

24)Computer adopts PLC, OMRON

25)Computer operating board adopt Thinget OP320A

26)transducer adopts Holip of Danfoss

27)output table: roller type

2)De-coiler capacity: 5T

3)Machine stand: welded by steel structure, shot blast after welding, get rid of inside stress

4)guide feeding stand type:side trolley type

5)The type of feeding and straightening: two rollers for clamping and feeding, five rollers for straightening.

6)Punching type: pre-Hydraulic punching before roller forming

7)Punching die material: Cr12Mov, quenching process

8)Hydraulic pre-punching: 3 sets of punching mould

9)diameter of shaft: ¢70㎜

10)diameter of roller: ¢150㎜

11)transmission: Gearbox driven

12)motor power of forming machine:15KW×2=30KW

13)forming speed:0-10m/min

14)roll station:17 stations ( subject to the final design)

15)Material of roller: GCr15, quenching hardness is HRC58°-60°

16)heat treatment: forging--temper--anneal--normalizing--quenching—temper

17)Coil thickness: 4mm

18)Adopts hydraulic cutting

19)material of cutting blade:Cr12

20)heat treatment of cutting blade:HRC58°-60°

21)tolerance of length:10m±2mm

22)motor of hydraulic station:7.5kw

23)hydraulic oil pump:gear pump CB-E314

24)Computer adopts PLC, OMRON

25)Computer operating board adopt Thinget OP320A

26)transducer adopts Holip of Danfoss

27)output table: roller type

Top