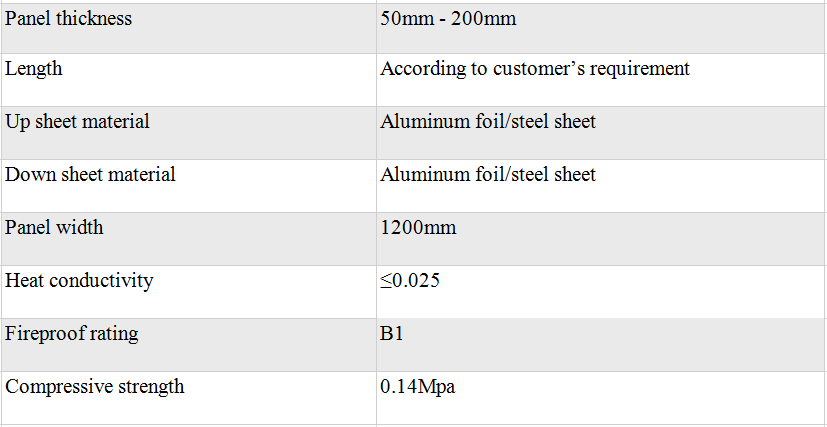

Phenolic Sandwich Panel

Phenolic Sandwich Panel

Phenolic Sandwich Panel

Phenolic Sandwich Panel

Phenolic Sandwich Panel

Phenolic foaming panel possesses the features of light weight, fireproofing, smokeless, non-poison without dropping. And it will not burn when meeting with open flame. The range of operating temperature is wide enough which reaches from -196℃ to +200℃. It can keep unshrinking without embrittlement in low-temperature environment. Because of the high percentage of close area of the phenolic foam, the heat conduction coefficient is accordingly low(lower than 0.030w/mk) and the heat-shielding performance is good with curtain water-resistance and water vapor permeability. These characteristics make phenolic foaming panel a good material for warm-keeping and energy-saving. It is also an ideal material for HVAC refrigeration project. Phenolic has the pheny structure which determines the stable size and the rate of change is lower than 1%.

The chemical components are steady and it is antiseptic and anti-aging especially resistant to the corrosion of organic solution, strong acid and weak base. It conforms to the international environmental standard that not using Freon as the foaming agent during the production process of foaming. Phenolic contains hydrogen, oxygen and carbon in its molecular structure so that even during the pyrolysis it only reveals non-poison, tasteless gas which is harmless to both the environment and human. It also accords to the environmental protecting standard of the country. Therefore, phenolic super sandwich panel is a quite ideal thermal insulation material satisfy fireproofing, heat insulation, energy conservation, elegant appearance and environmental protection at the same time.

At the moment, there is an increasing development of phenolic foaming material in developed countries. It has been widely applied to all kinds of areas of building, national defense, foreign trade, storage, energy and so on. Phenolic material counts for 40% among the foamed plastic for sound-insulation and heat-preservation which American construction industry uses. Japan has founded association for promoting phenolic foam.

Phenolic panel possesses fantastic effect of heat preservation as a kind of organic material. It is also different from other organic materials(PU, POLY, extruded sheet) because phenolic panel can easily reach the standard of B1 level fireproof panel without adding fire retardant. The fireproof performance of phenolic panel is much better than other organic materials and its process is already mature and stable. The cost of phenolic panel is far below the cost of PU and phenolic panel doesn't need to use fuoride foaming agent in the production process. In the area of ventilating duct, phenolic panel is the best of numerous materials.