-

1) Packaging film shrinks evenly, no accumulation

-

2) Total motor power: 22kw

-

3)Power input: 15KVA

-

4)Power input: AC380V, three-phase four-wire system

-

5)Temperature range: environment temperature 140℃(thermal shrinking room);

-

6)Thermal shrinking room: 2.5*2*1m (L*W*H) (50mm PU panel);

-

7)Mode of delivery: active transmission roller

-

8)Power of rollers: 1.5KW

-

9)Max transmission weight:120kg

-

10)Conveyor width: 1300mm

-

11)Pinch type: cylinder lock, mechanism transmission

-

12)The biggest sealing length: 1800mm

-

13)The biggest sealing height: 1000mm

-

14)The biggest shrinking measurement: width 1200mm*height 1000mm

-

15)Sealing temperature: not more than 250℃

-

16)Sealing time: 1s-1.5s

-

17)The circulation fan power: about 0.55kw*4

-

18)Cooling motor power: 0.17kw

-

19)Packing efficiency:3 packages/min (stacking specification 1m*1.2m*0.6m)

-

20)Outline dimension: 2m*8m*2m( from pyrocondensation to cooling)

-

21)Back roller (after cooling): not more than 5m (according to customer’s requirements)

-

22)Packing material: PE、PVC、POF etc pyrocondensation material

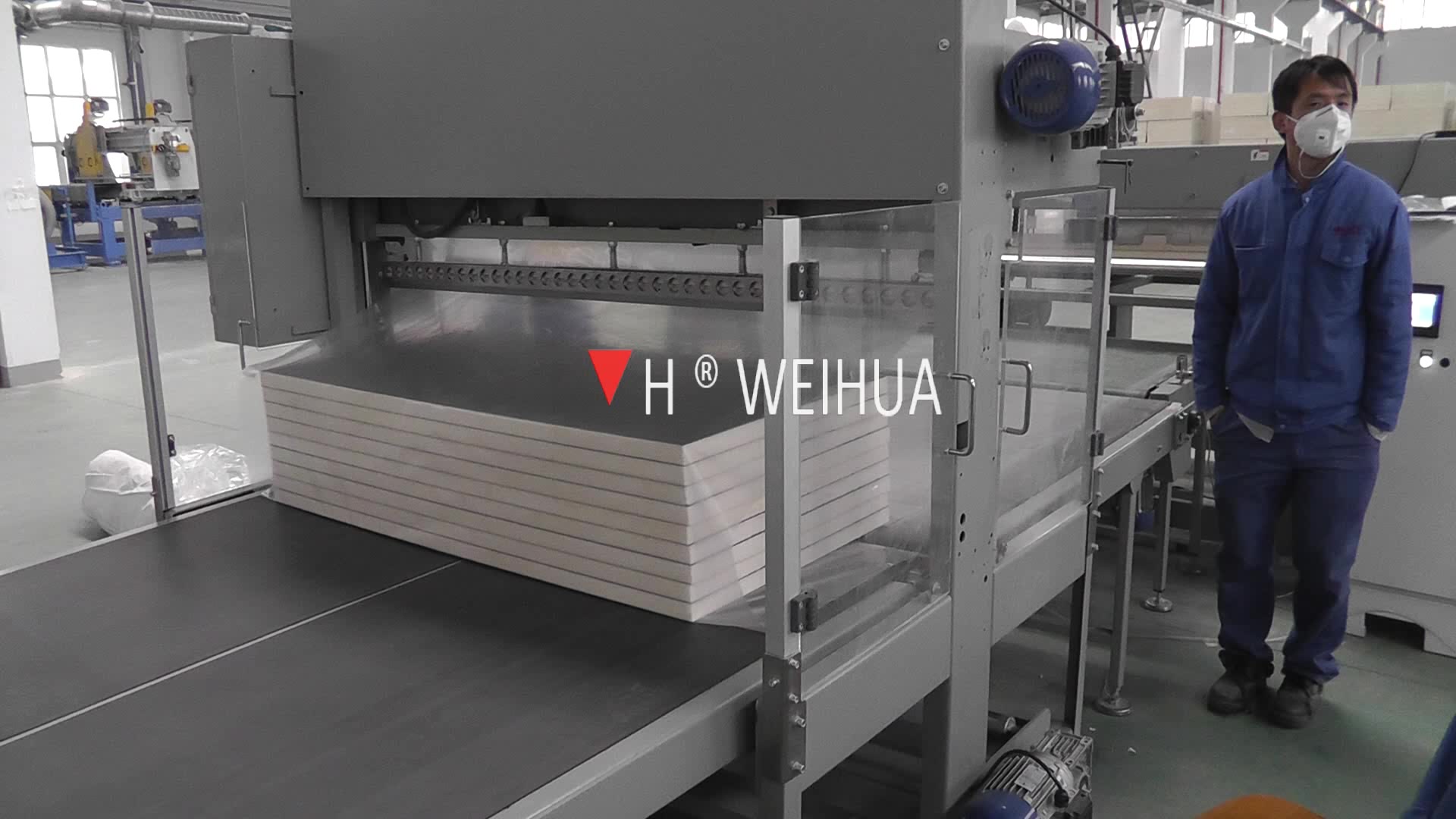

Thermoplastic Film Wrapping Machine

Thermoplastic Film Wrapping Machine