Foaming machine is the core

part of the continuous sandwich panel production line which directly affects

the quality of production panel. Due to the difficulty of foaming technology

and the inability to see the foaming process, it was veiled with a mysterious

veil.

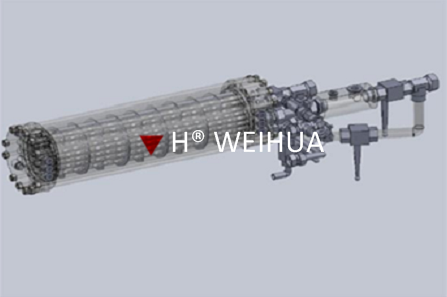

WEIHUA has endeavored to the research of foaming machines for many years. This technology involves 1) fluid mechanics, 2) fluid heat exchange, 3) gas-liquid emulsification, 4) chemical raw materials 5) electrical automation control, 6) Common-rail injector technology for internal combustion engines (needle tip injection technology), 7) precision machinery design and manufacturing heat treatment, and 8) pentane explosion-proof safety and other core technologies in the subdivided fields.

With the promotion and

application of highly fire-retardant PIR B1 grade polyurethane, pentane is put

into use as a foaming agent, and the new foaming machine will become the core

configuration in the production line. After nearly two decades of continuous

development and optimization of foaming machines, WEIHUA has now fully mastered

all core technologies and successfully applied it to multiple production lines

at home and abroad. These technologies include:

Flow Ratio Control Technology:With the promotion and application of highlyTemperature Control Technology:

Self-cleaning Mixing Head

Technology: WEIHUA Patent and Research, is nowHigh-speed Shear Mixing Emulsification Technology:

-

1) Unit pouring volume: 120—500g/s

-

2) Against-spurt pressure range of pouring injector:12-18MPa,Rated 15Mpa

-

3) Pressure adjustment of pouring injector: pneumatic, adjustable online

-

4) System control of each component flow: auto closed-loop control(suitable for manual)

-

5) Working type: continuous high-pressure operation

-

6) Volume of chemical material working tank Poly 300L ISO 300L Catalyst 150L Catalyst A 150L Catalyst B 150L Foaming agent 150L

-

7) Six-component material flow (adjustable mixing ratio) PLOY 50~300g/s ISO 50~300g/s Fire retardant 5~50g/s Catalyst A0.6~6g/s Catalyst B0.6~6g/s Foaming agent 5~50g/s. (Customer can decide on how many components they need. And foaming agent can be 141B, Pentane, etc)

-

8) Tolerance of material temperature control: ±2℃

-

9) Heating of temperature control: 6×6Kw,Cooling: 20000Kcal/h

-

10) Input power:45kw

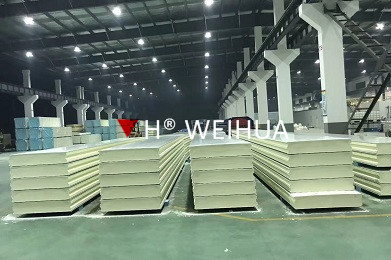

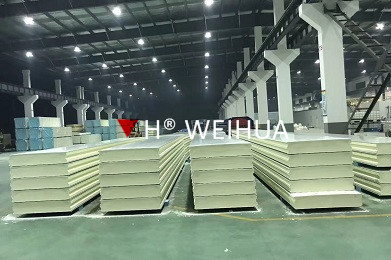

Foaming performance of the production panel is pretty good. This is cold storage sandwich panel of which thickness is 250MM and fire retardant rating is B2. The percentage of close area is high, and heat conductivity coefficient is favorable.

According to Montreal Protocol on Substances that Deplete the Ozone Layer published in 1989, Europe and America have ceased the use of CFC. Cyclopentane is considered as a replacement of CFC in Europe since 1993. and Now the progress to phase out CFC/HCFC is ongoing in China, India, UAE and other developing countries. For foaming system with pentane as foaming agent, the following factors need to be considered:

1. Pentane Storage System

Cyclopentane

storage system is mainly used for storing cyclopentane which is unloaded from

tank truck and then feeding the material to foaming machine automatically. The

design, operation and safety of the system strictly conforms to the TUV

standard.

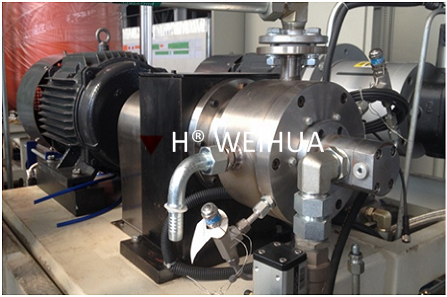

2. Pentane Foaming Machine

All pentane-related components and pipelines

on the foaming machine are installed in one small room where probe and double

exhaust system are equipped to ensure the security. A detection head is installed

on the storage tank.

The security system is controlled by independent electrical cabinet which is

separate from operation cabinet.

3. Pentane Security System

Pentane detection devices will be installed in the pantane leakage zone and possible leakage zones, including double belt

conveyor and material spraying area and material storage tank. Besides these, WEIHUA will offer below services which helps customer run this line safely and reliably.

Two Components Foaming Machine

Two Components Foaming Machine

Two Components Foaming Machine

Two Components Foaming Machine