Corrugated Sheet Roll Forming Machine

Corrugated Sheet Roll Forming Machine

Corrugated Sheet Roll Forming Machine

Corrugated Sheet Roll Forming Machine

Corrugated Sheet Roll Forming Machine

TECHNICAL PARAMETER

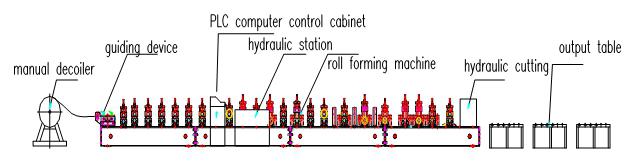

FLOW CHART

APPLICATION

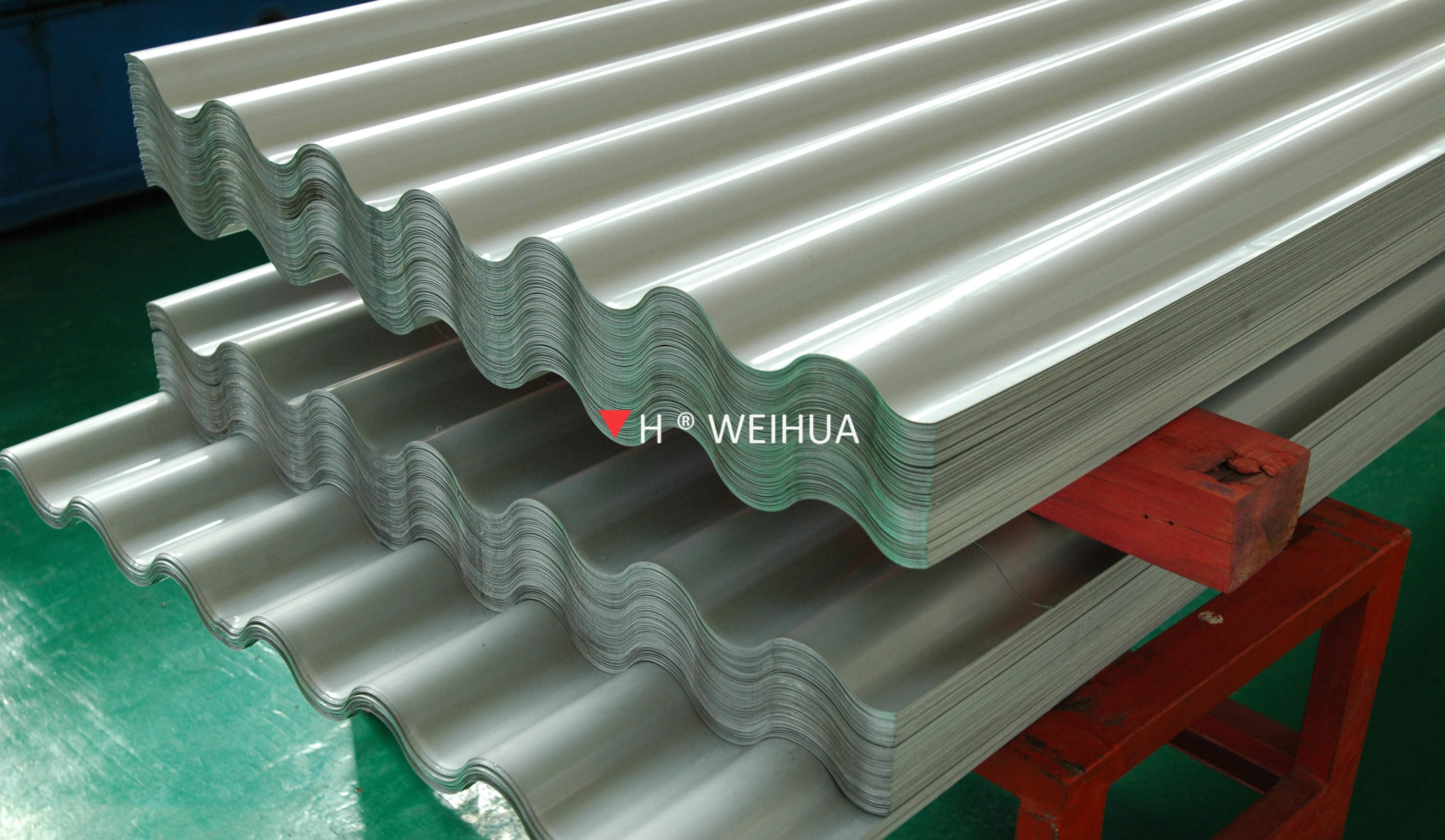

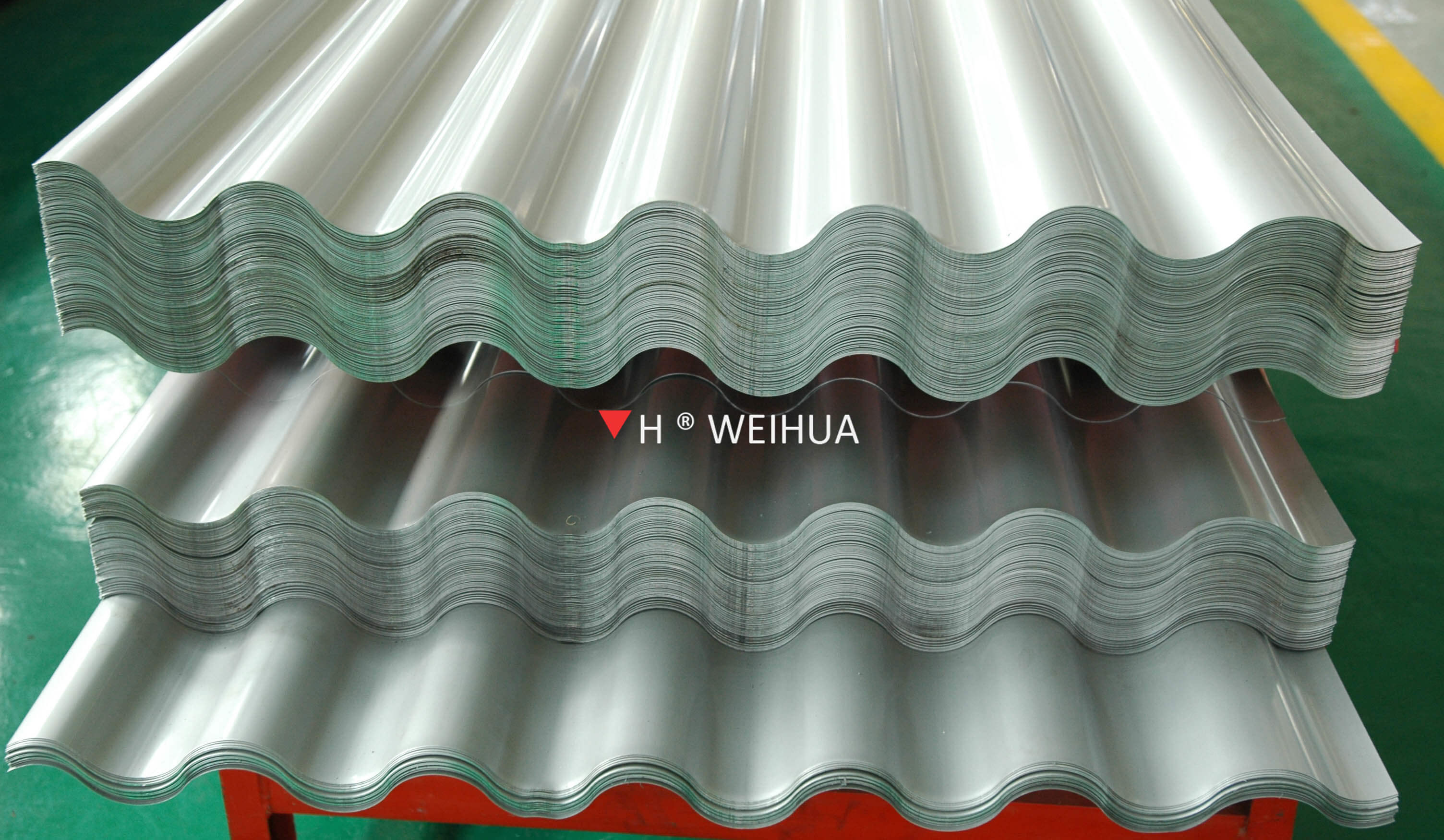

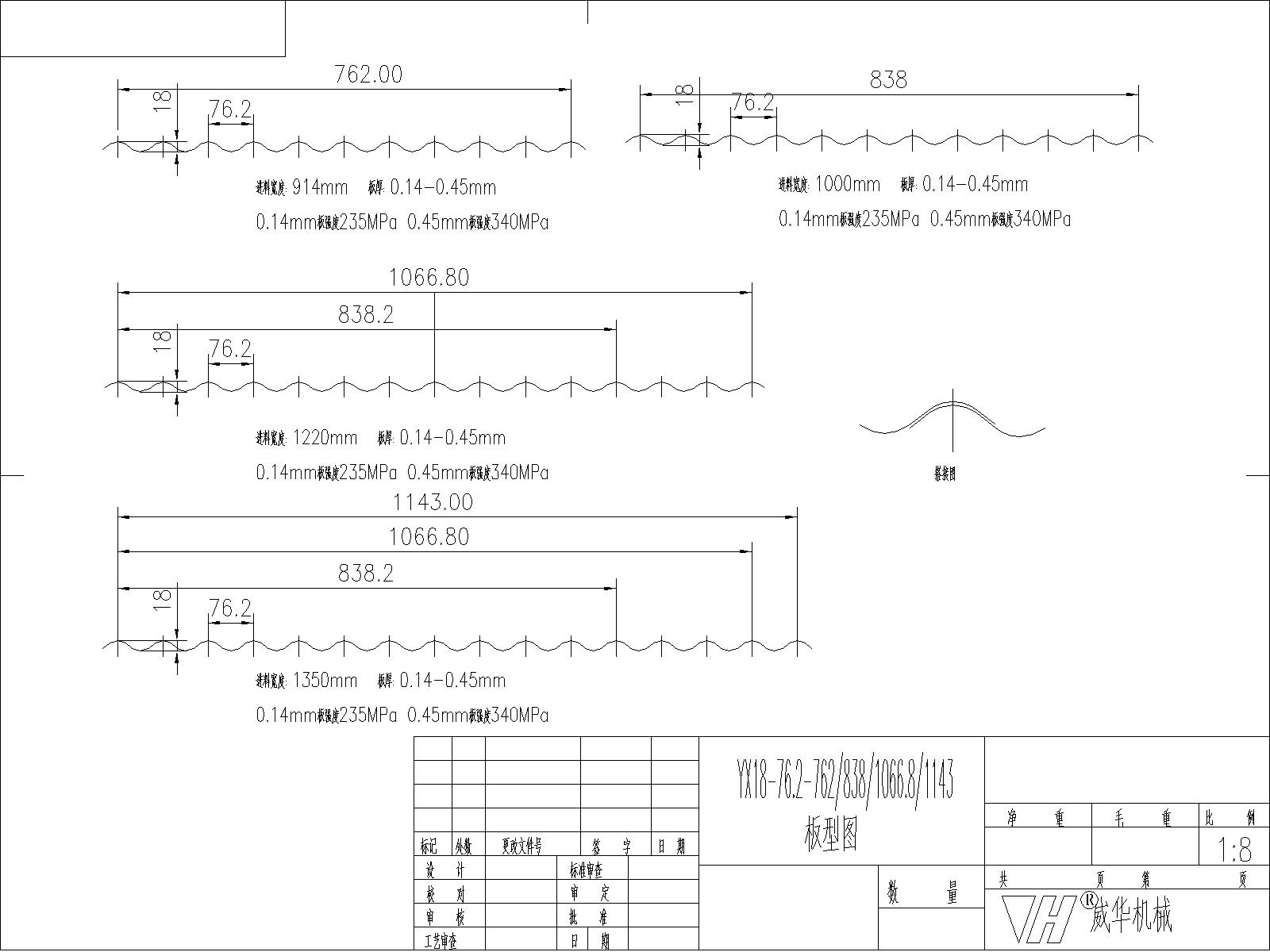

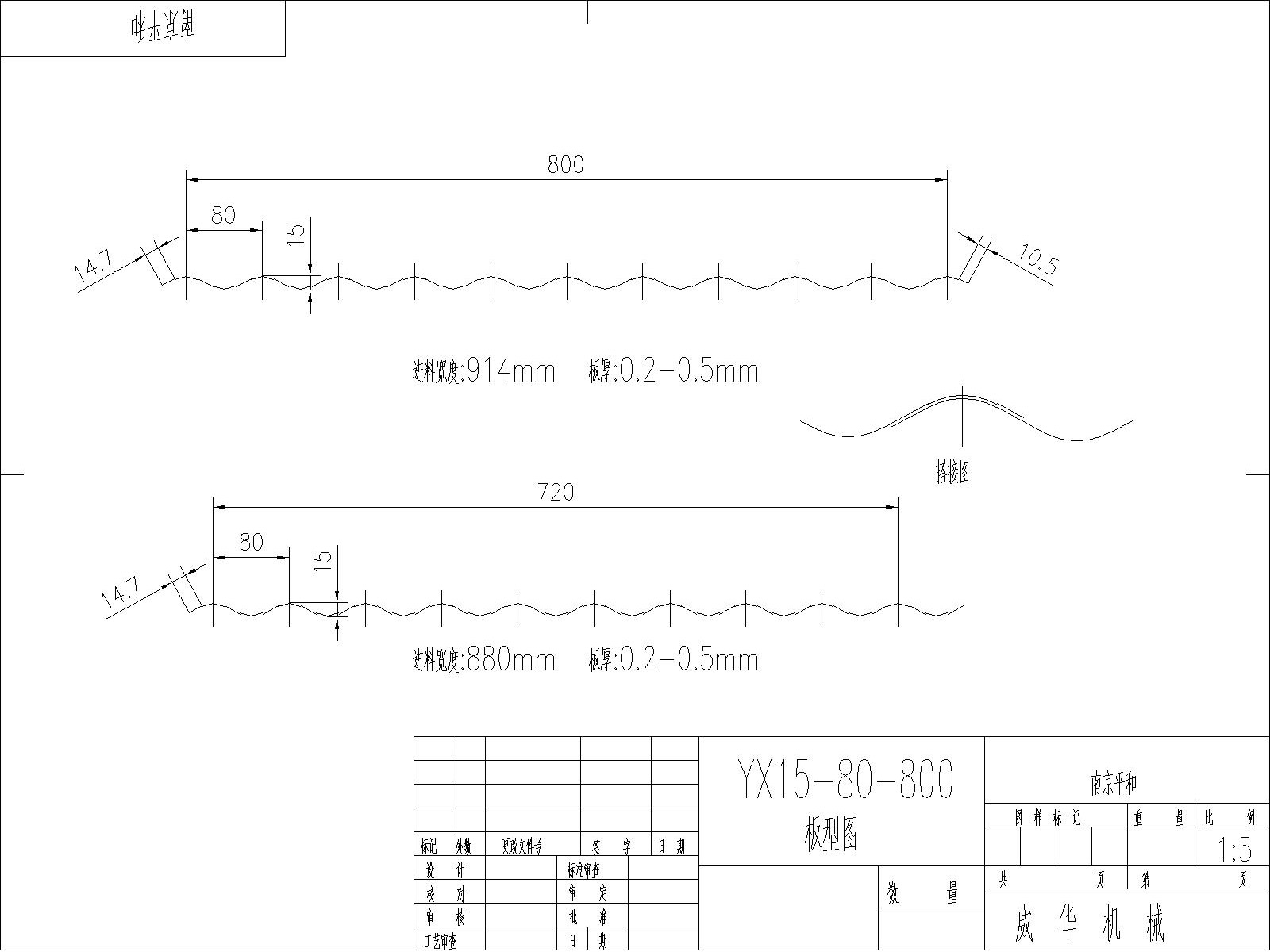

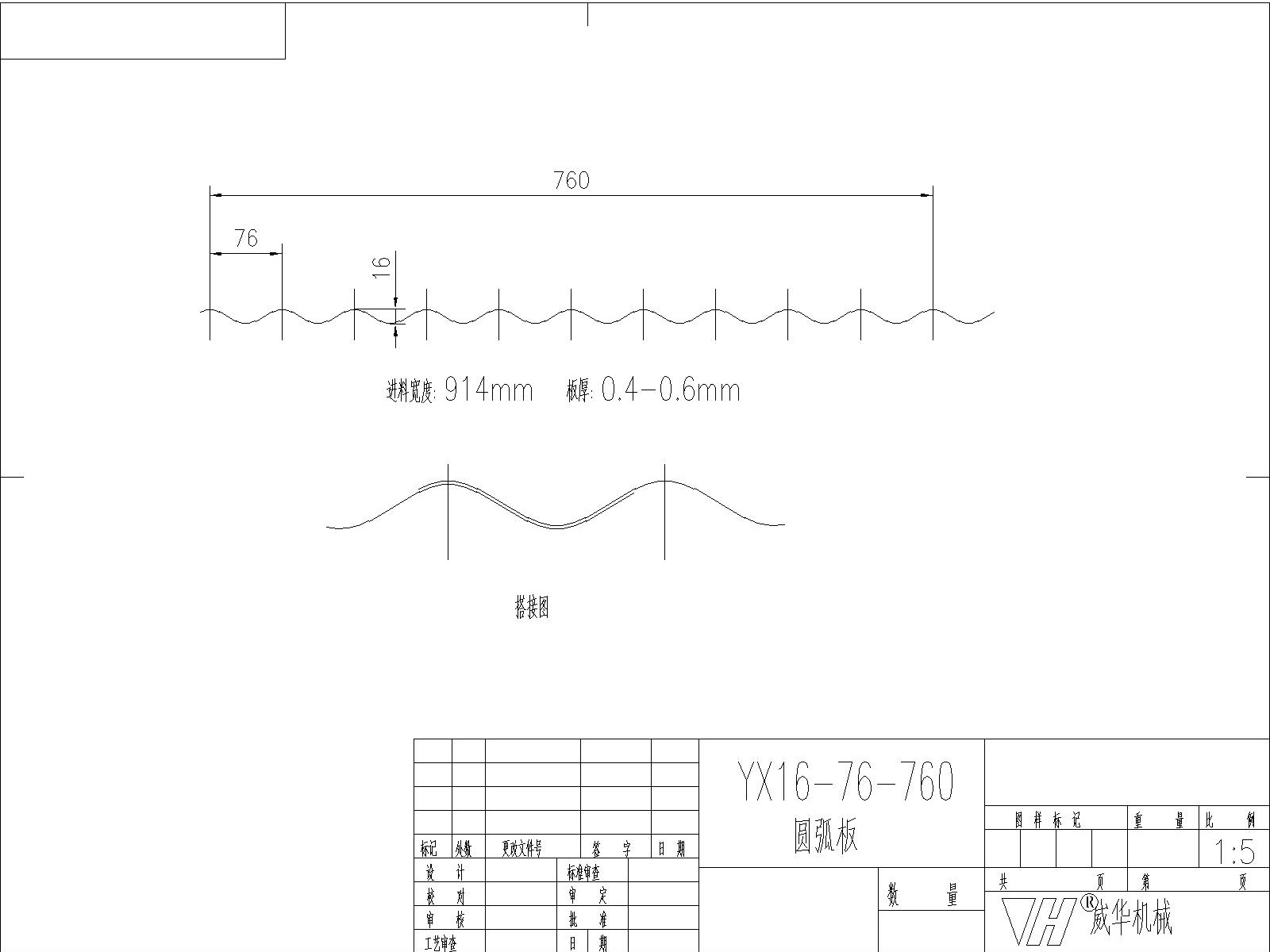

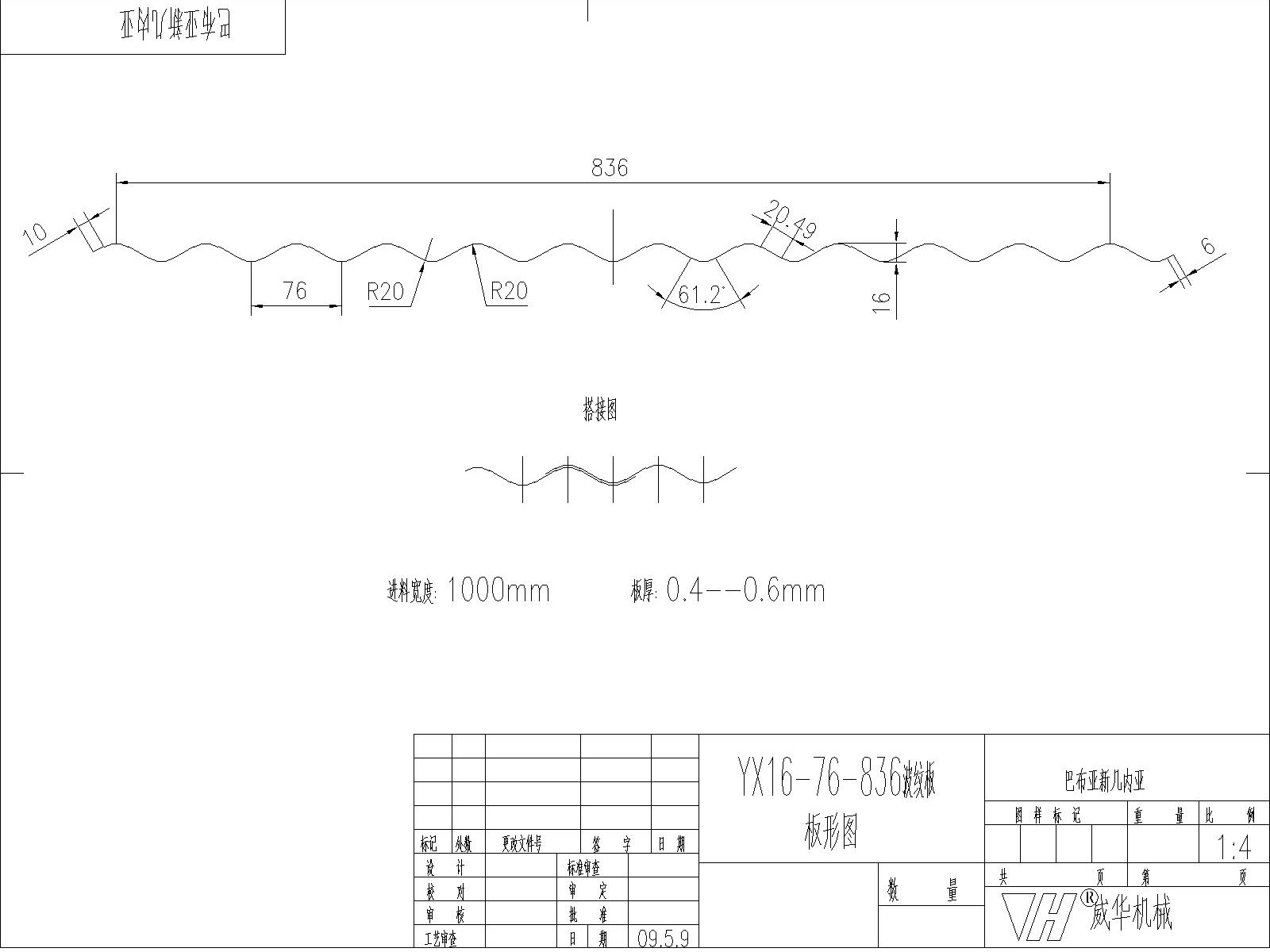

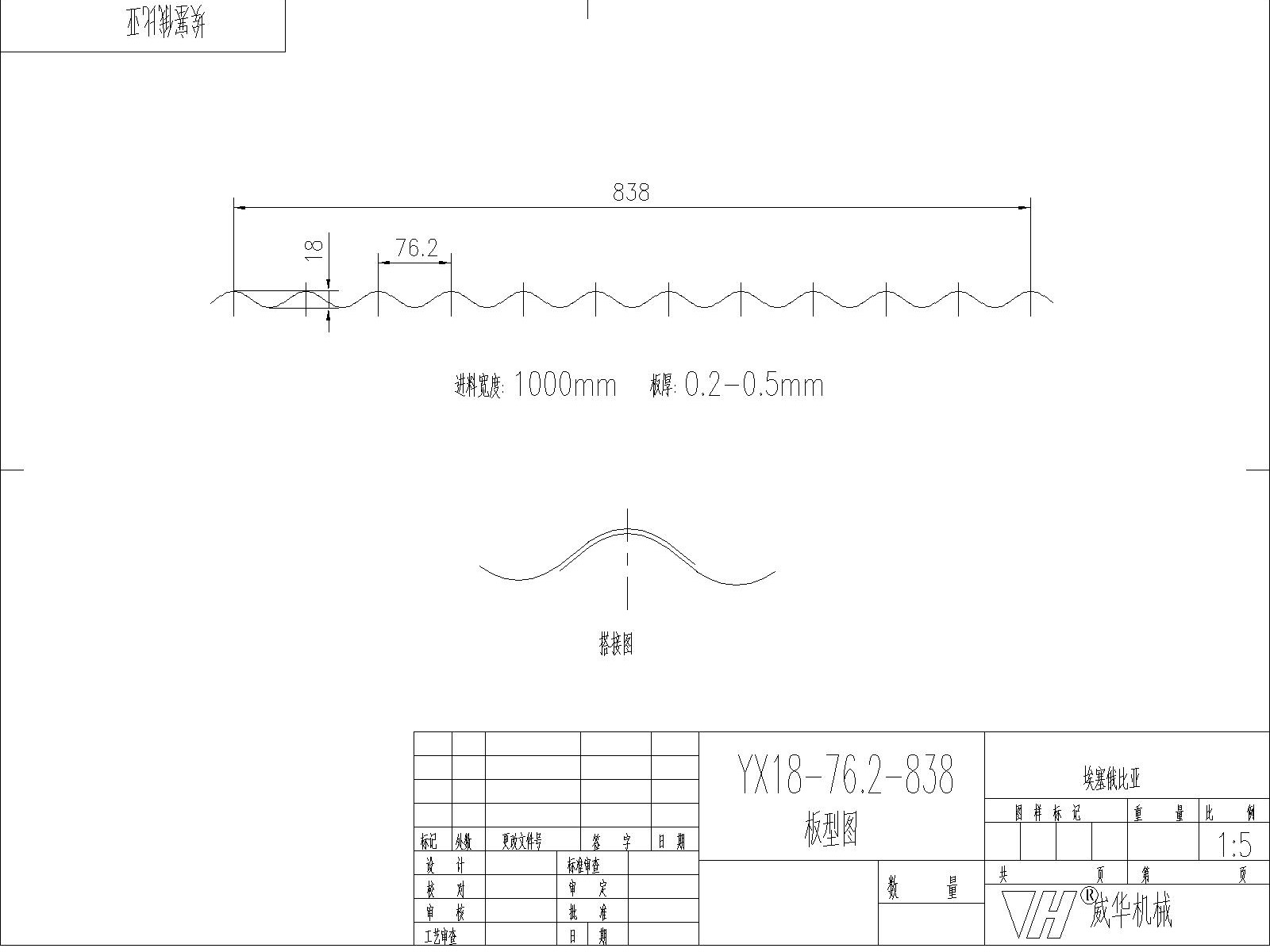

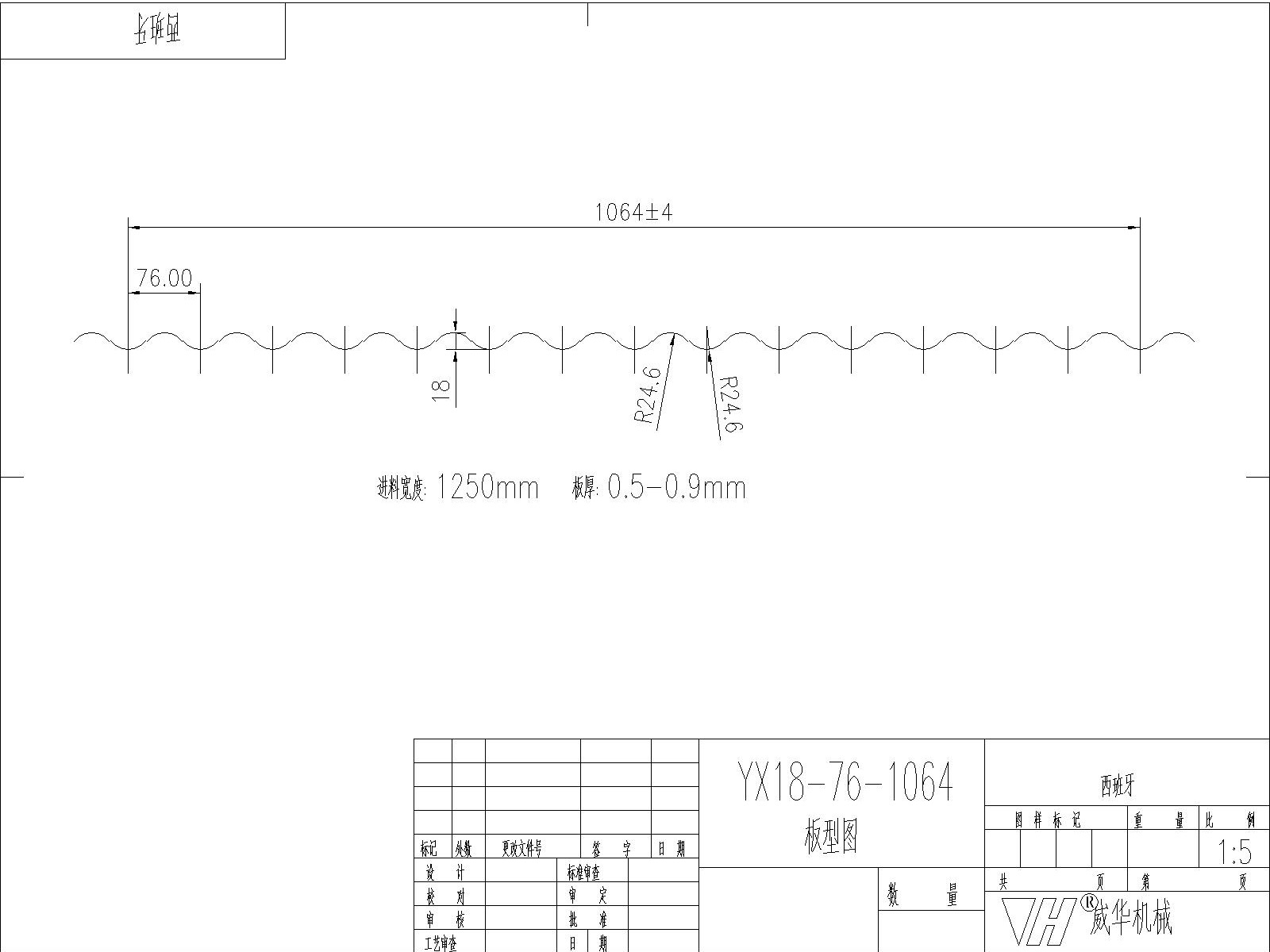

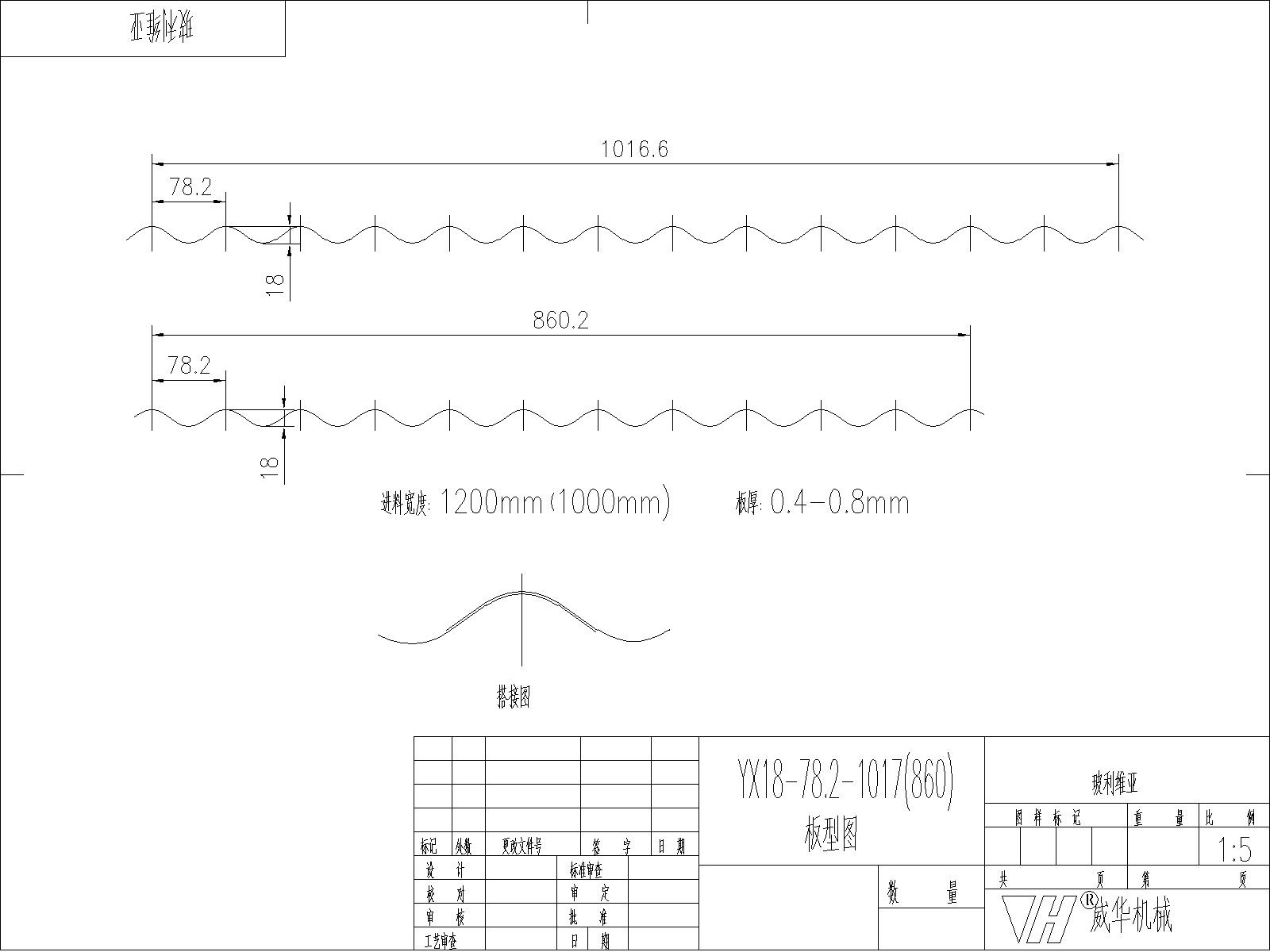

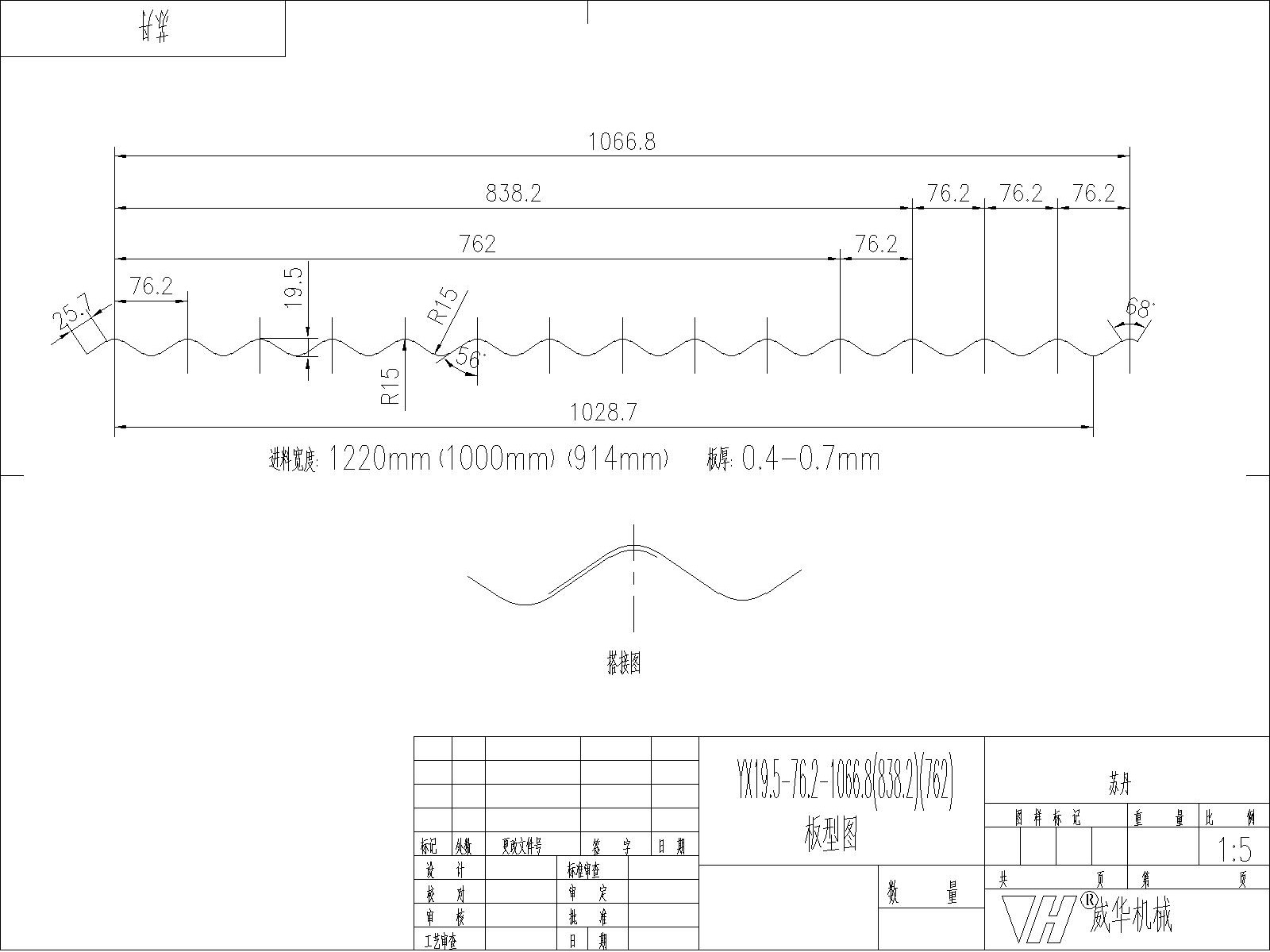

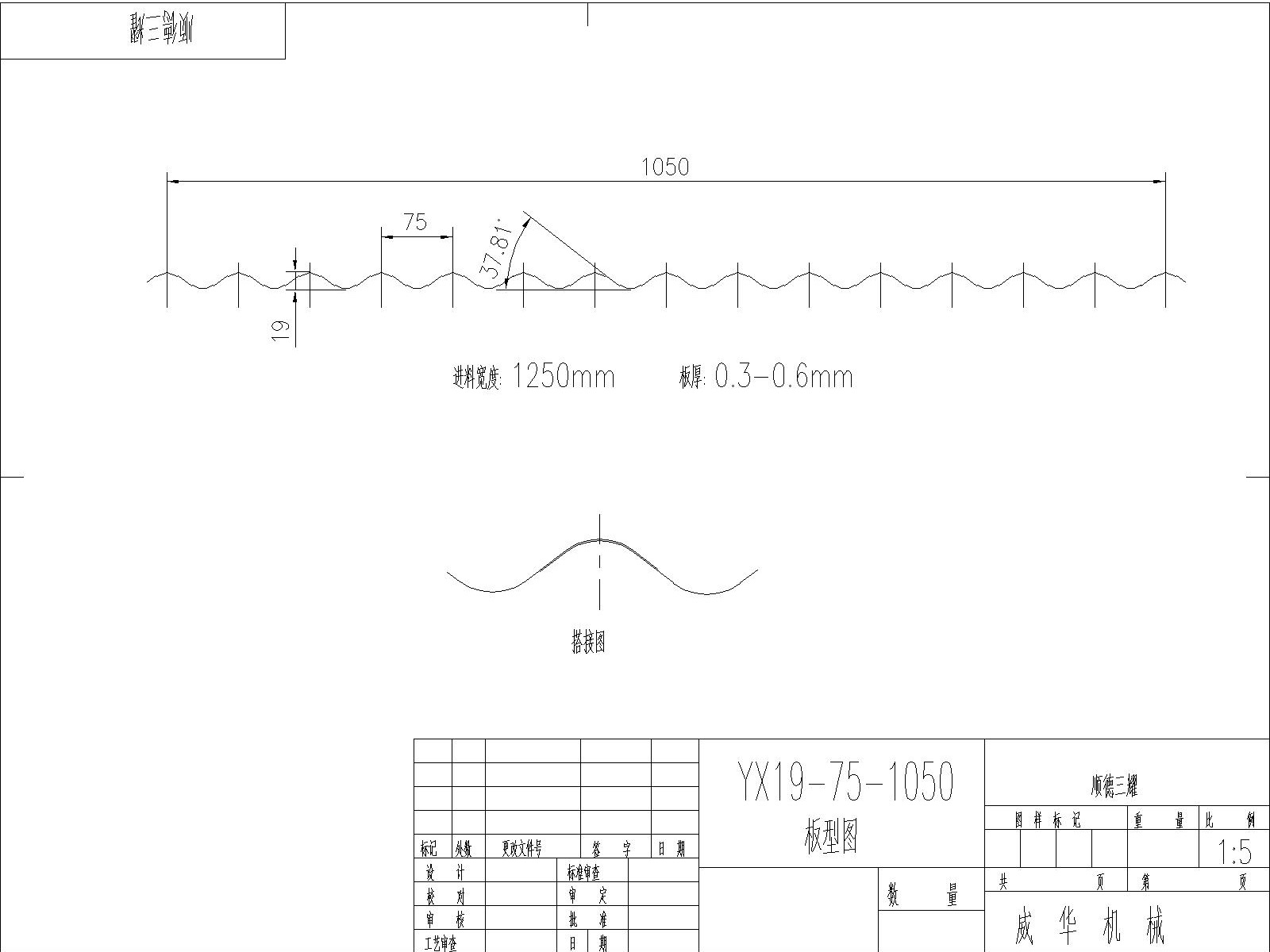

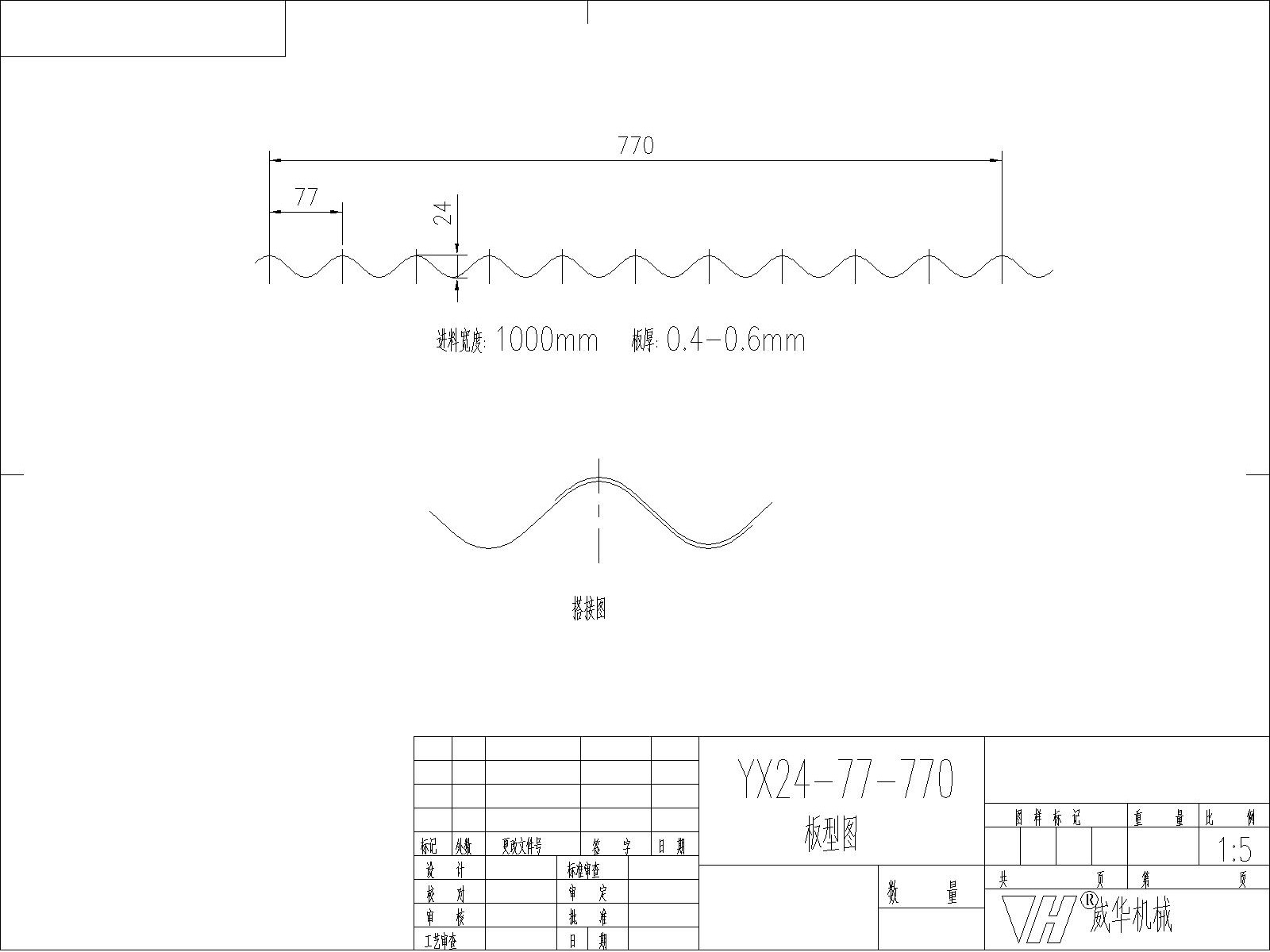

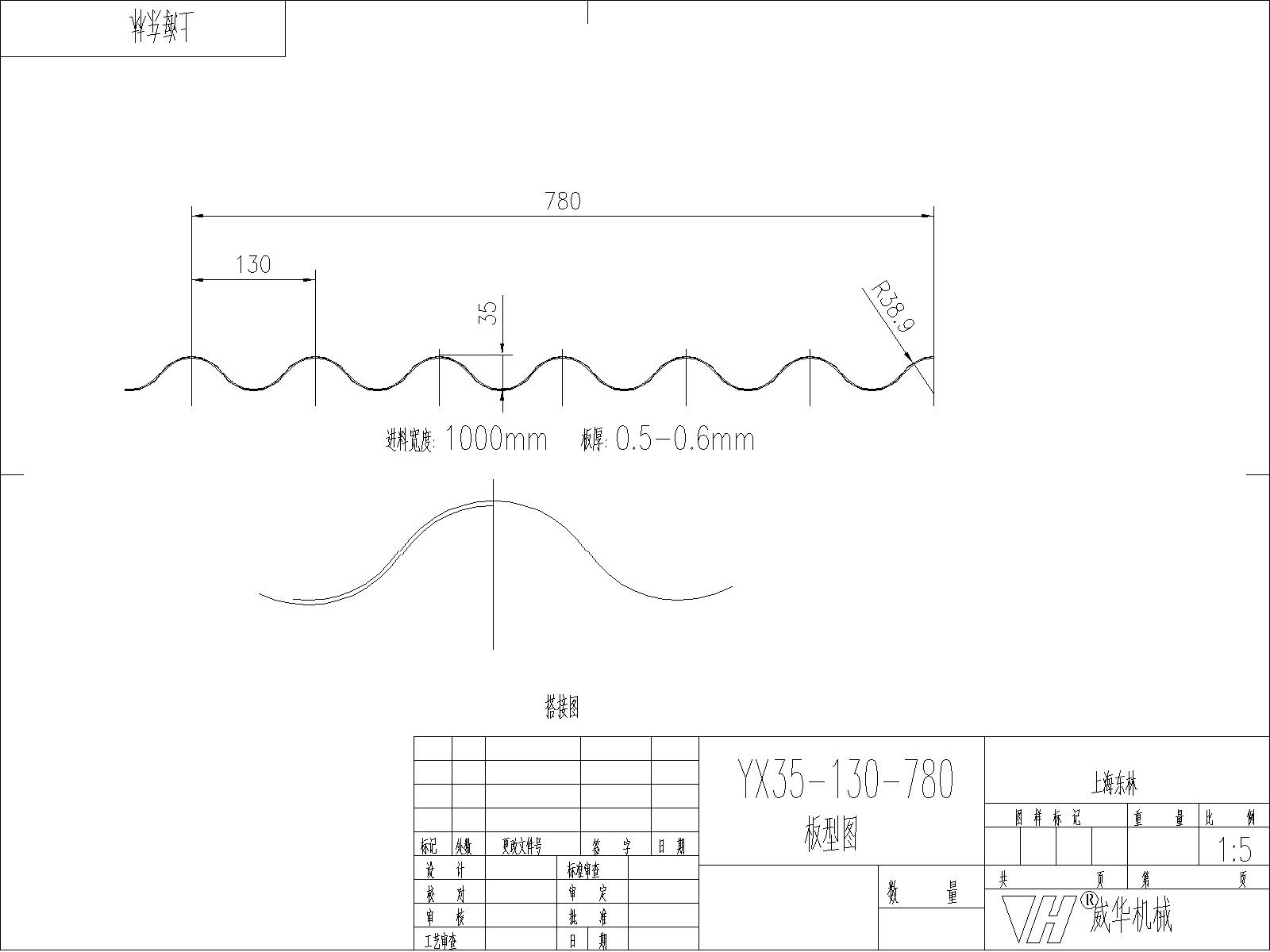

PROFILE

1.Manual decoiler: manual decoil, passitive expansion

2.Inner diameter of decoiler: 508mm, 610mm

3.Decoiler capacity: 5T

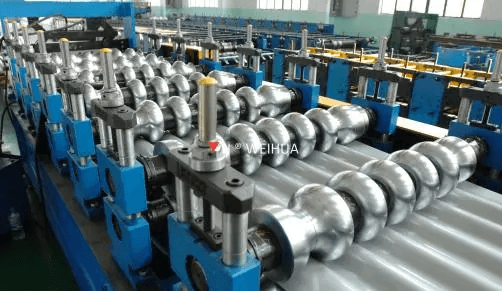

4.Machine stand: welded by steel structure, shot blast after welding, get rid of inside stress

5.Motor power of forming machine:7.5KW

6.Motor power of hydraulic station:3KW

7.Hydraulic oil pump:gear pump CB-E314

8.Roll stand:30 stations

9.Forming speed:10m/min

10.Material of roller:No. 45 forging steel

11.The surface of roller coating chrome:single surface 0.05mm

12.Type of forming machine: wallboard type chain transmission

13.Diameter of shaft: ¢75mm

14.Height of center: 130mm

15.Chain: 16A

16.Cutting ways: hydraulic forming cutting

17.Material of cutting blade: Cr12, Quenching hardness HRC60°-62°

18.Thickness of steel coil: 0.3-0.6mm

19.Panel width of feeding: 1220mm

20.Tolerance of length:10m±2mm

21.Specific size of profile: conform to roll forming panel GB/T12755-2008 standard used for china construction

22.Form of guiding with feeding station:side trolley type

23.Transducer: Hongquan (Taiwan Brand)

24.Computer adopts PLC,Mitsutishi FX-IS Series

25.Hydraulic systemic working pressure: 12Mpa

26.Computer control system: whole machine adopts industrial computer PLC control, operating board adopts Xinjie OP320A

27.Output table: roller type

28.Voltage: 380V50HZ3PH

2.Inner diameter of decoiler: 508mm, 610mm

3.Decoiler capacity: 5T

4.Machine stand: welded by steel structure, shot blast after welding, get rid of inside stress

5.Motor power of forming machine:7.5KW

6.Motor power of hydraulic station:3KW

7.Hydraulic oil pump:gear pump CB-E314

8.Roll stand:30 stations

9.Forming speed:10m/min

10.Material of roller:No. 45 forging steel

11.The surface of roller coating chrome:single surface 0.05mm

12.Type of forming machine: wallboard type chain transmission

13.Diameter of shaft: ¢75mm

14.Height of center: 130mm

15.Chain: 16A

16.Cutting ways: hydraulic forming cutting

17.Material of cutting blade: Cr12, Quenching hardness HRC60°-62°

18.Thickness of steel coil: 0.3-0.6mm

19.Panel width of feeding: 1220mm

20.Tolerance of length:10m±2mm

21.Specific size of profile: conform to roll forming panel GB/T12755-2008 standard used for china construction

22.Form of guiding with feeding station:side trolley type

23.Transducer: Hongquan (Taiwan Brand)

24.Computer adopts PLC,Mitsutishi FX-IS Series

25.Hydraulic systemic working pressure: 12Mpa

26.Computer control system: whole machine adopts industrial computer PLC control, operating board adopts Xinjie OP320A

27.Output table: roller type

28.Voltage: 380V50HZ3PH

Top