Tile Roll Forming Machine

Tile Roll Forming Machine

Tile Roll Forming Machine

Tile Roll Forming Machine

Tile Roll Forming Machine

TECHNICAL PARAMETER

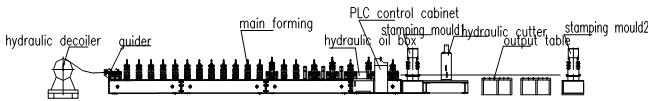

FLOW CHART

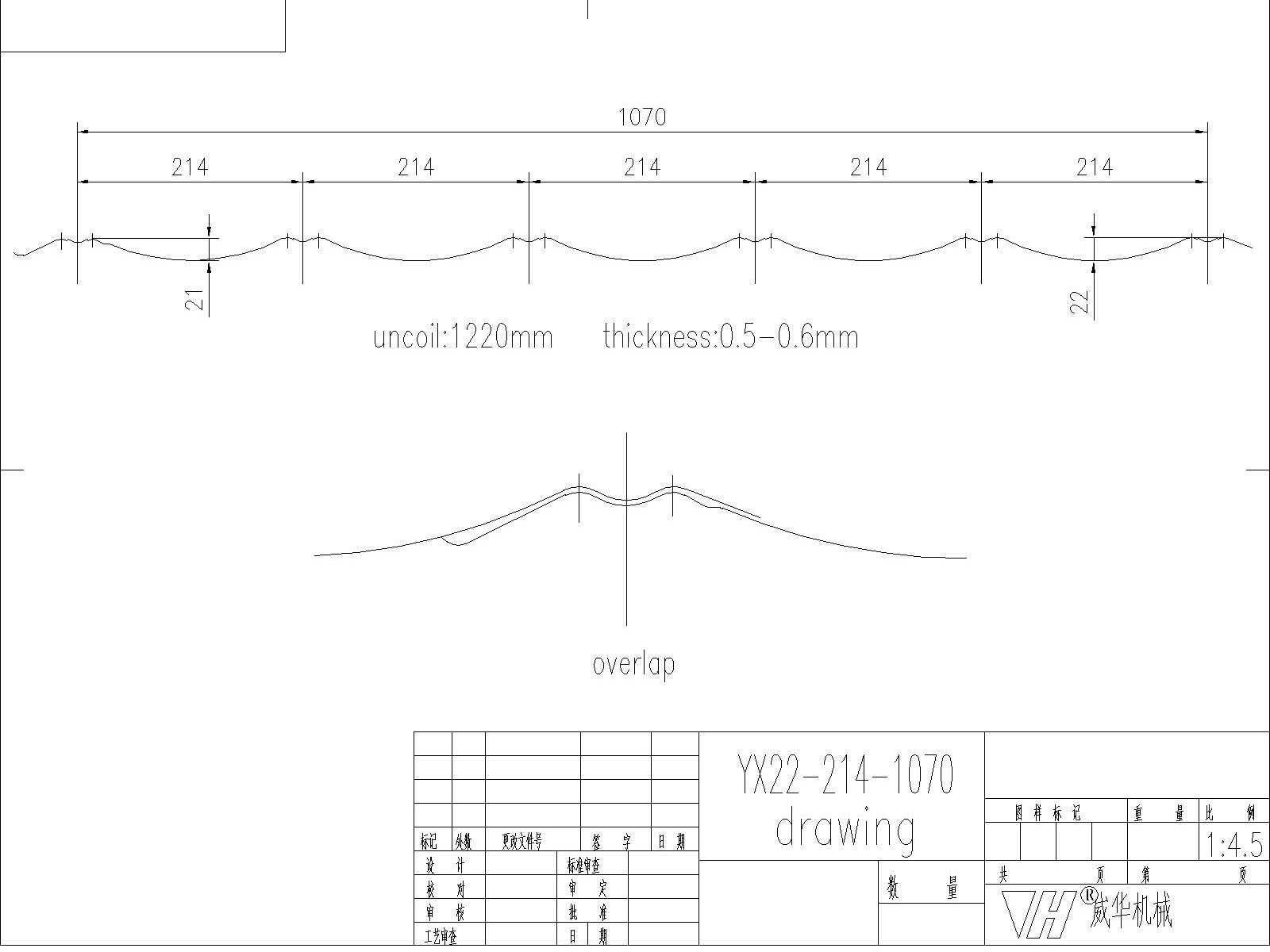

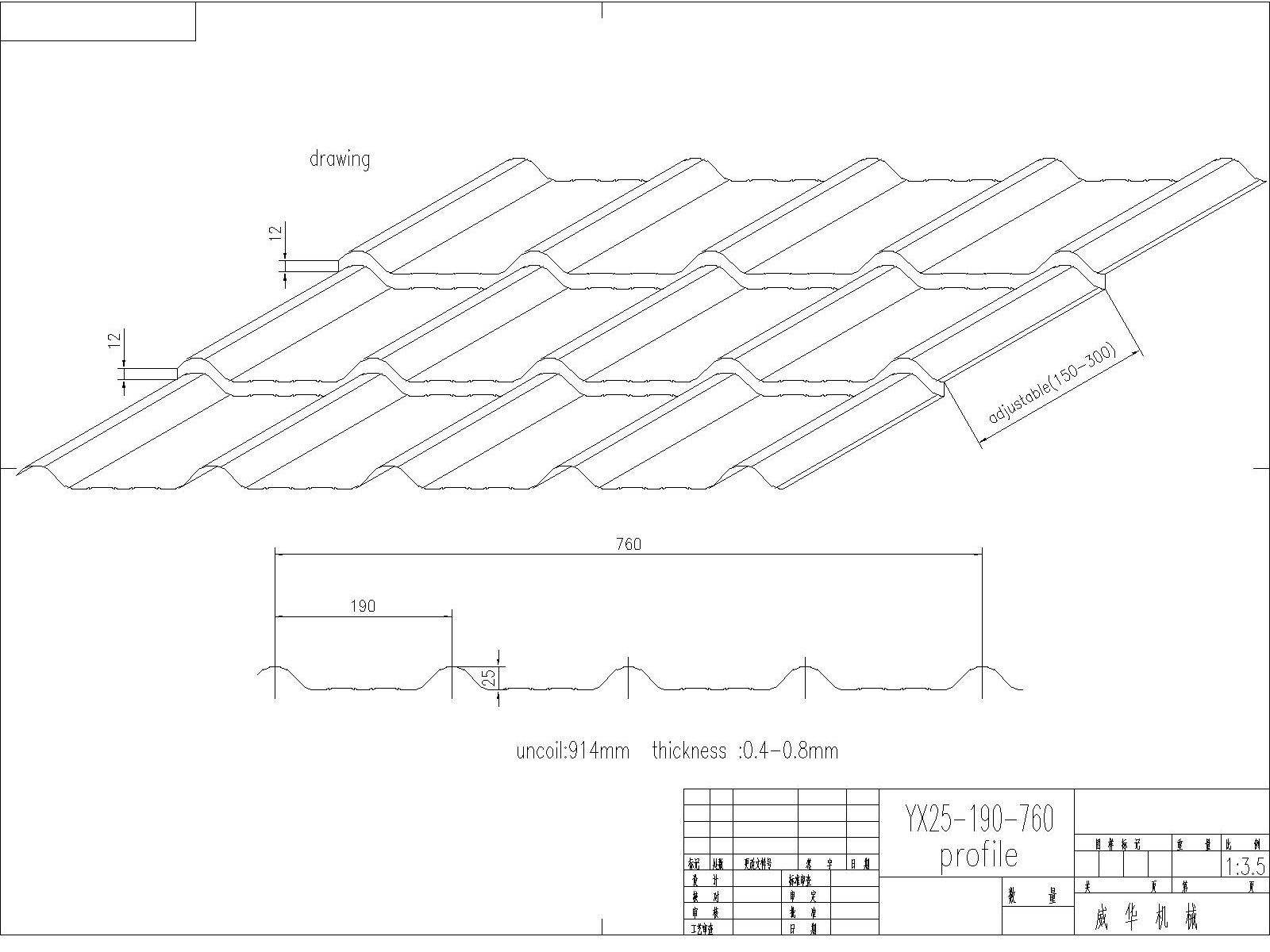

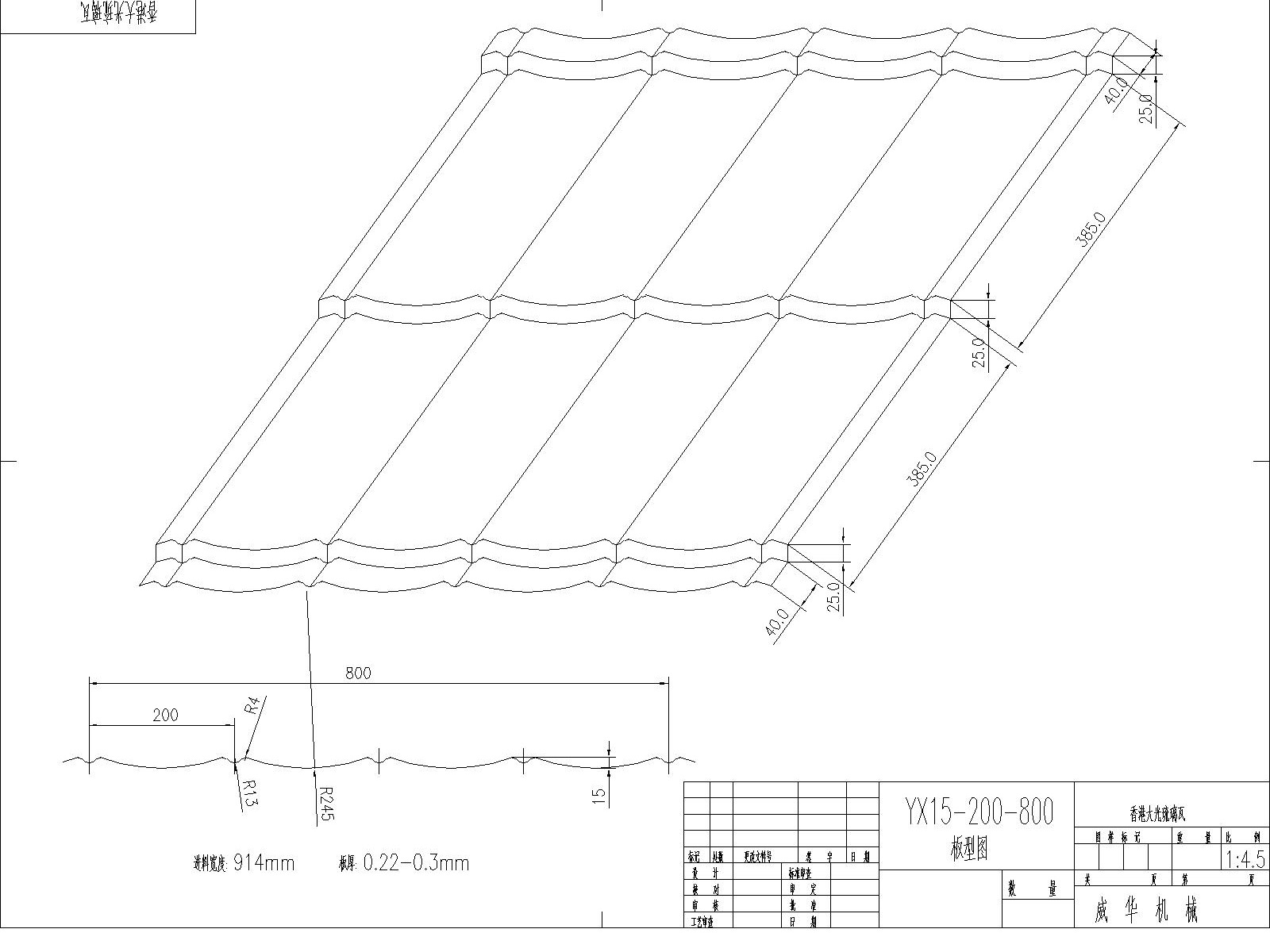

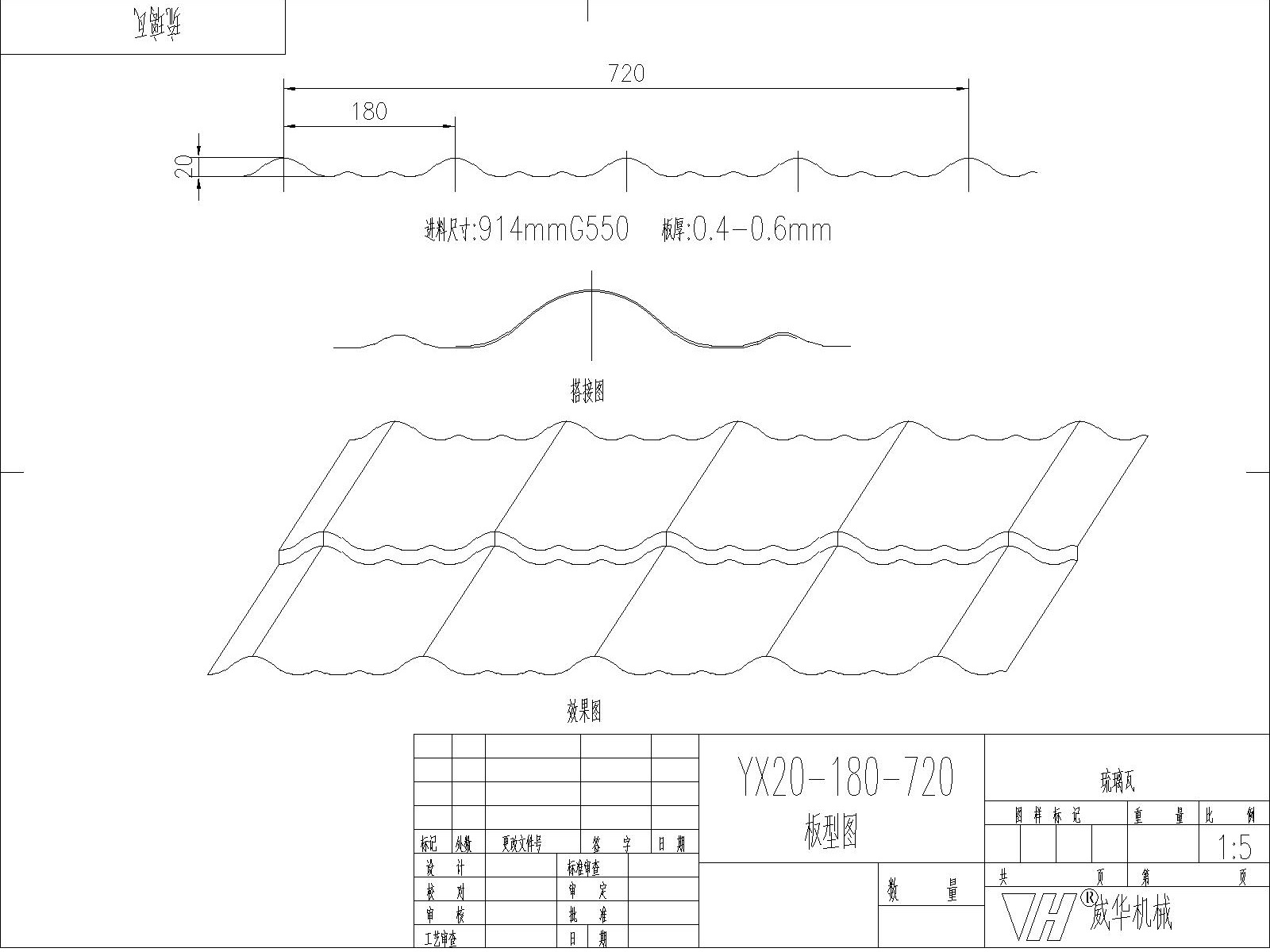

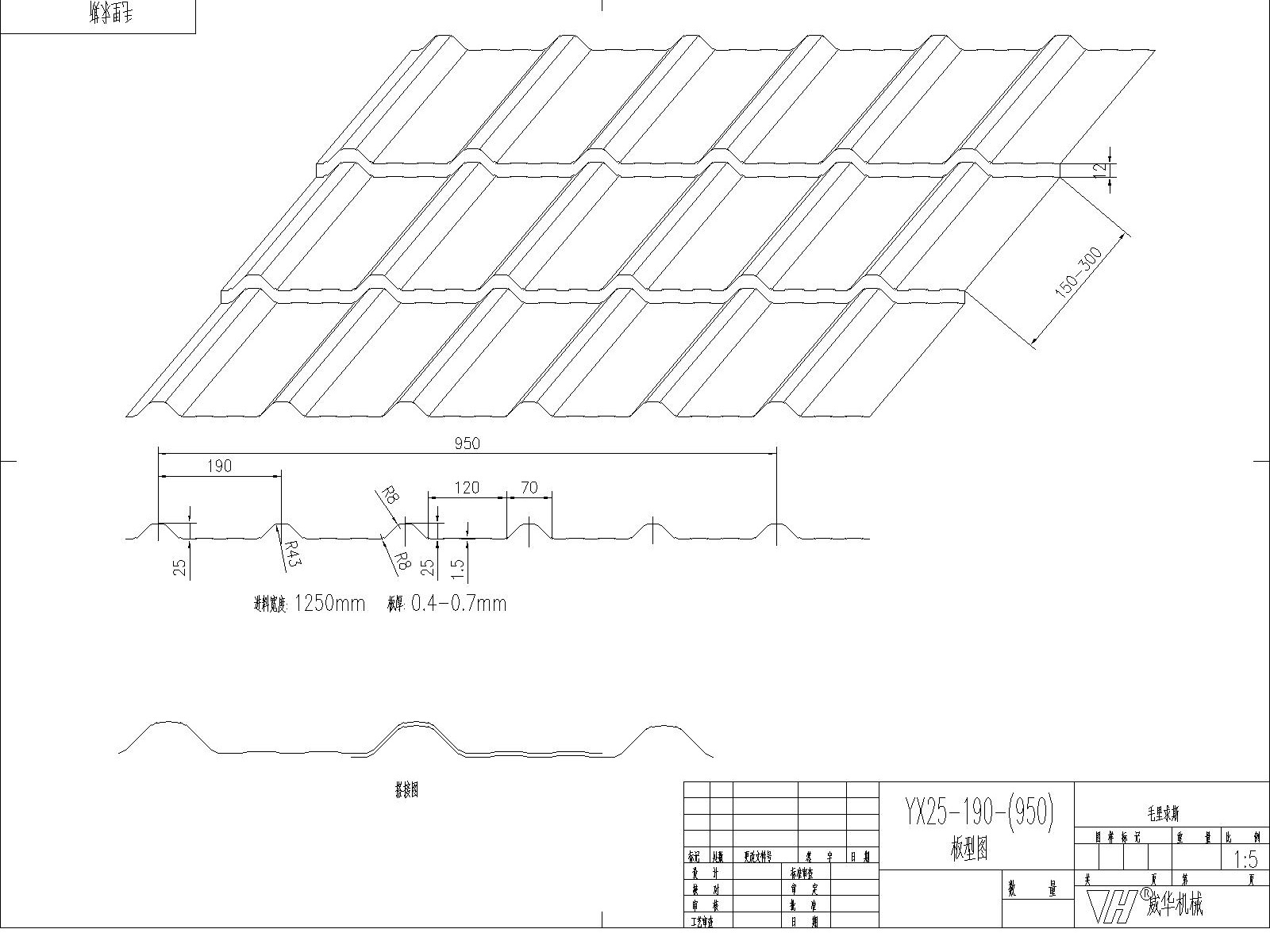

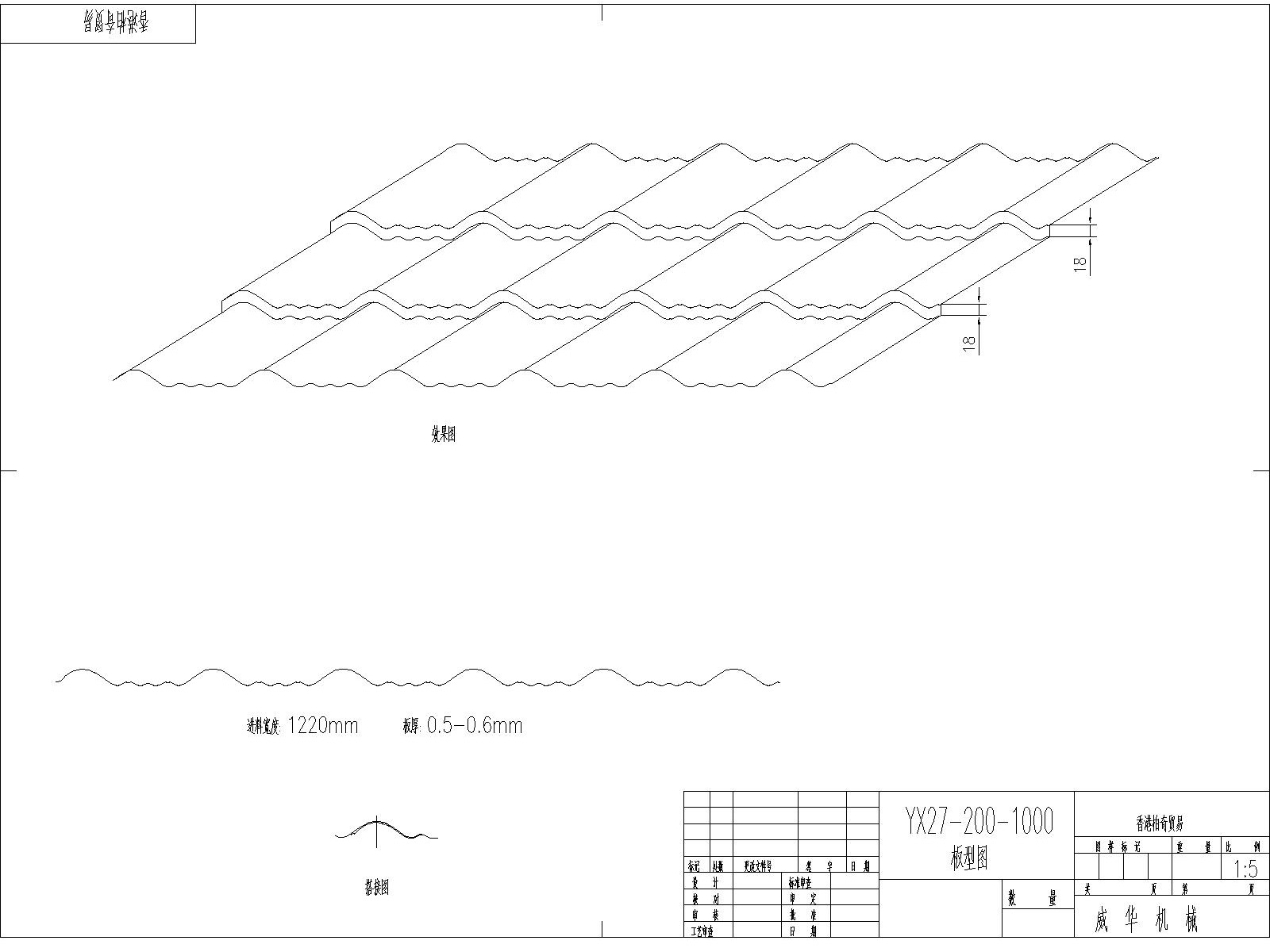

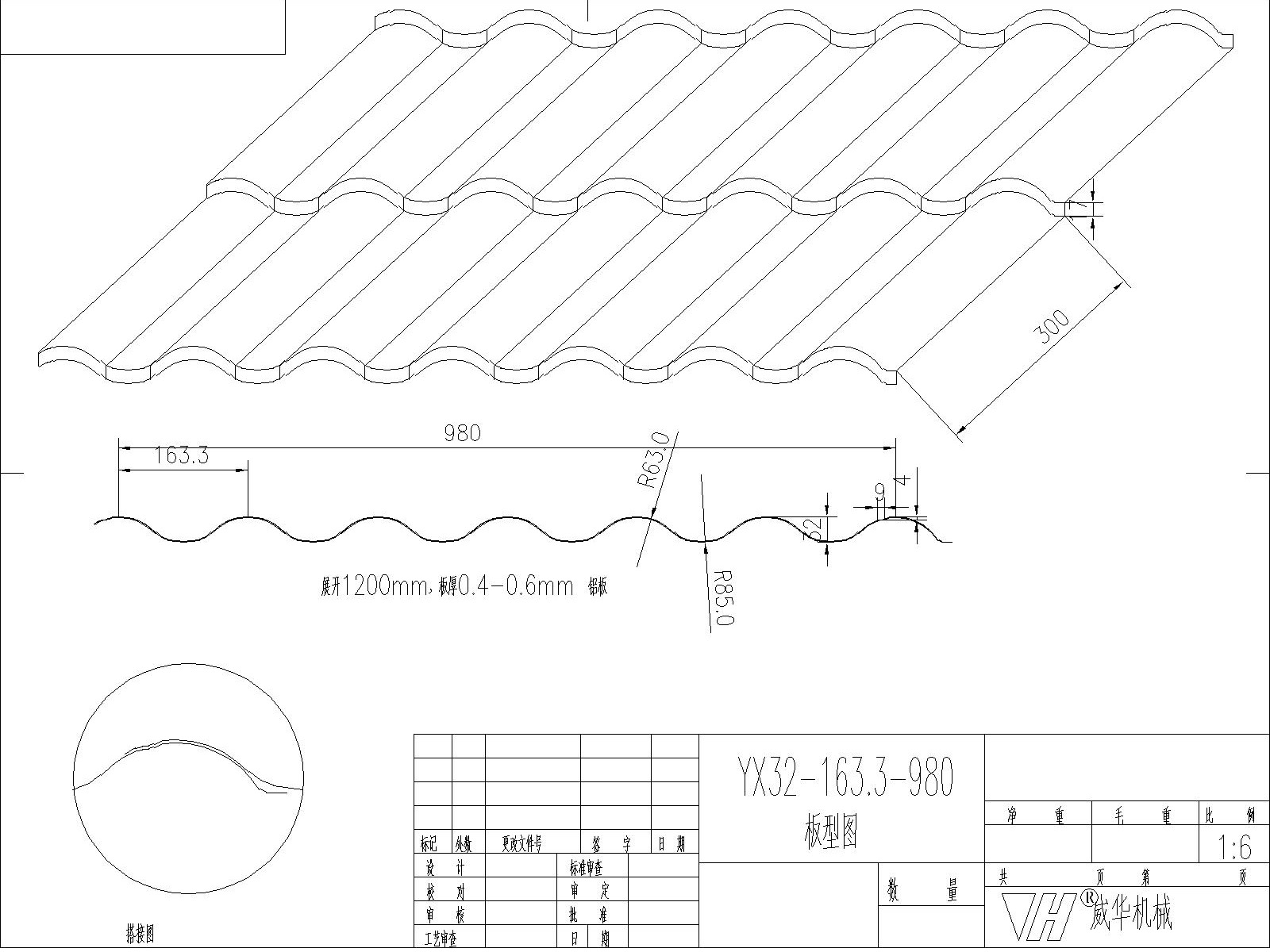

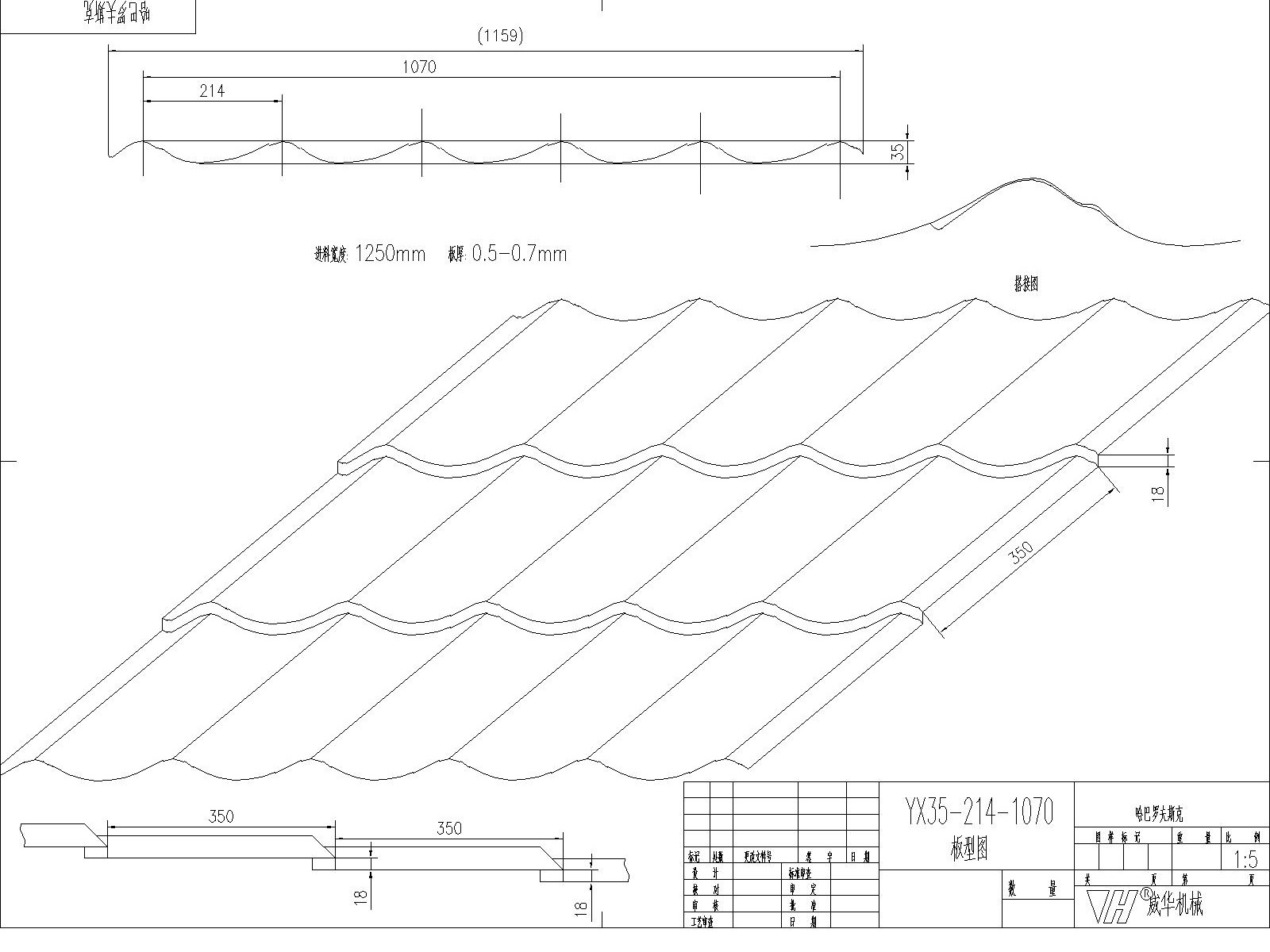

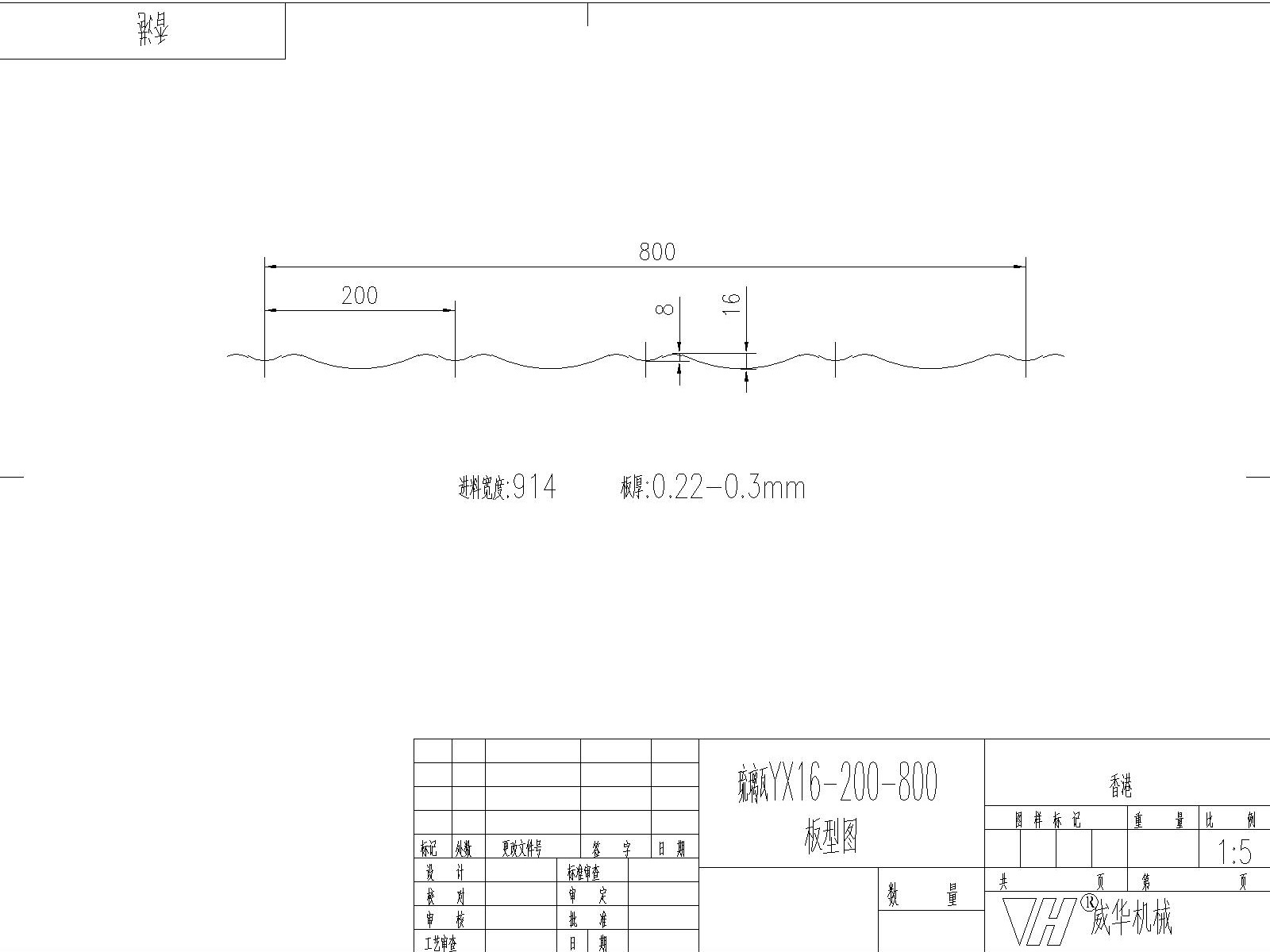

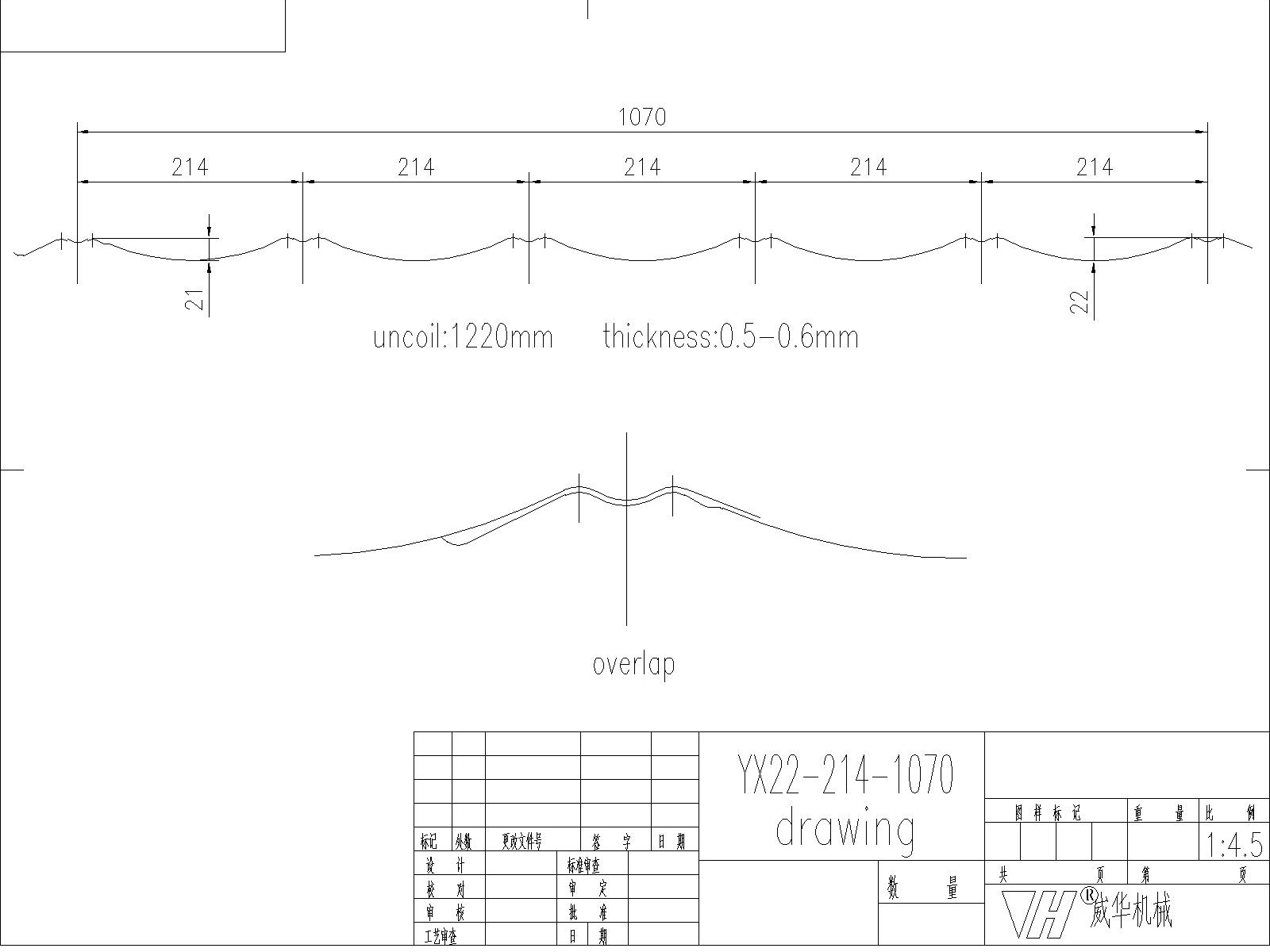

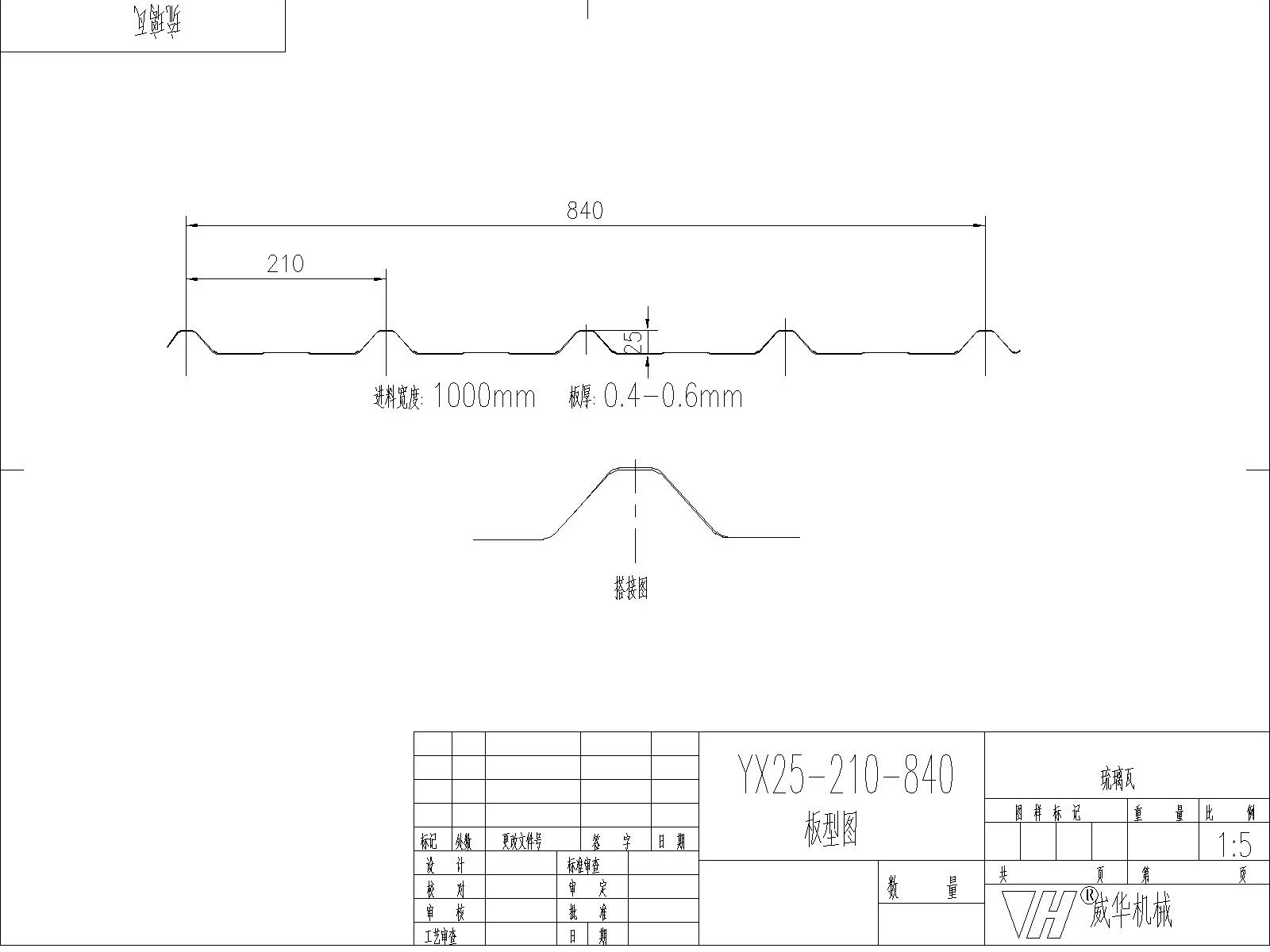

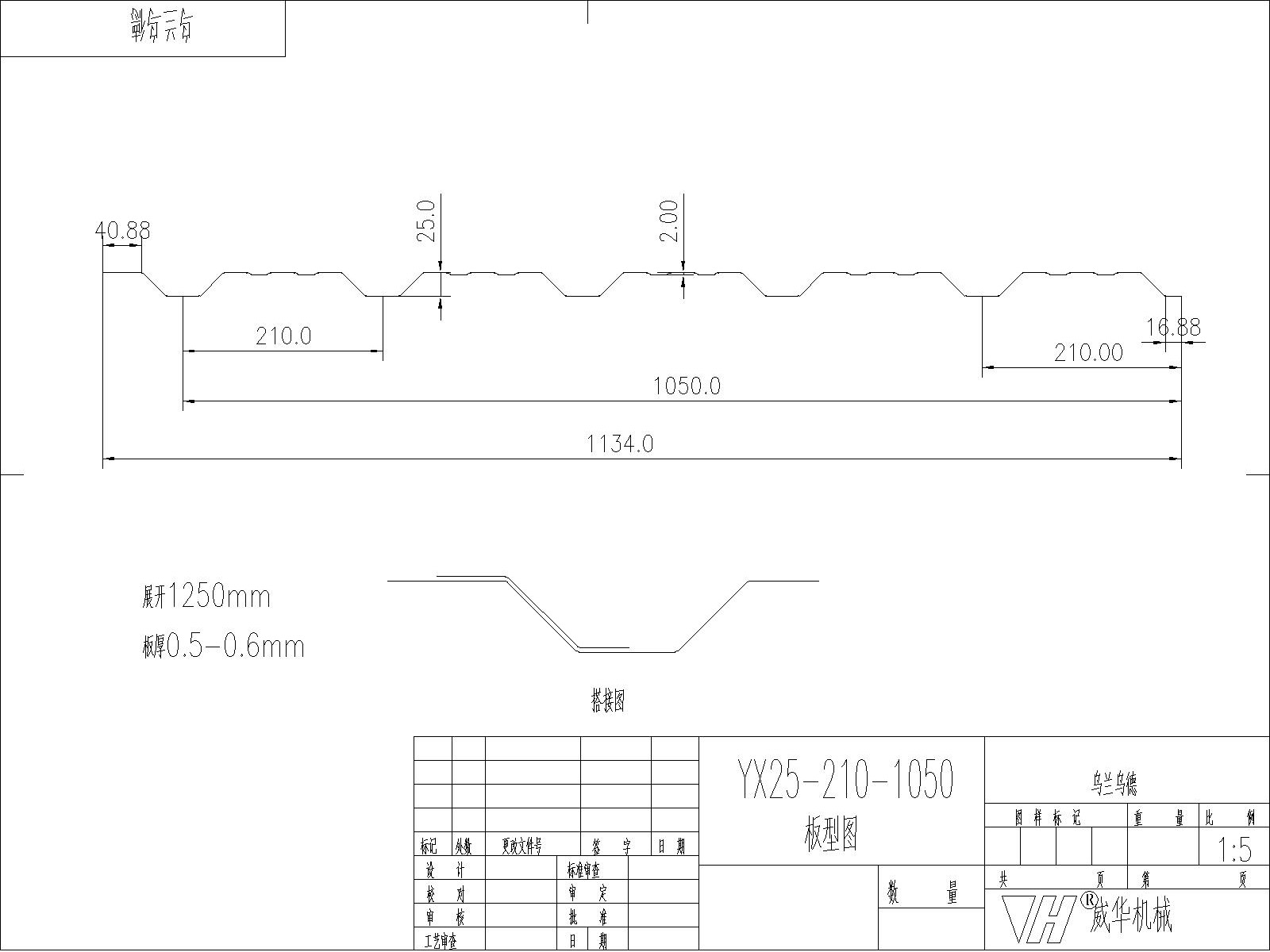

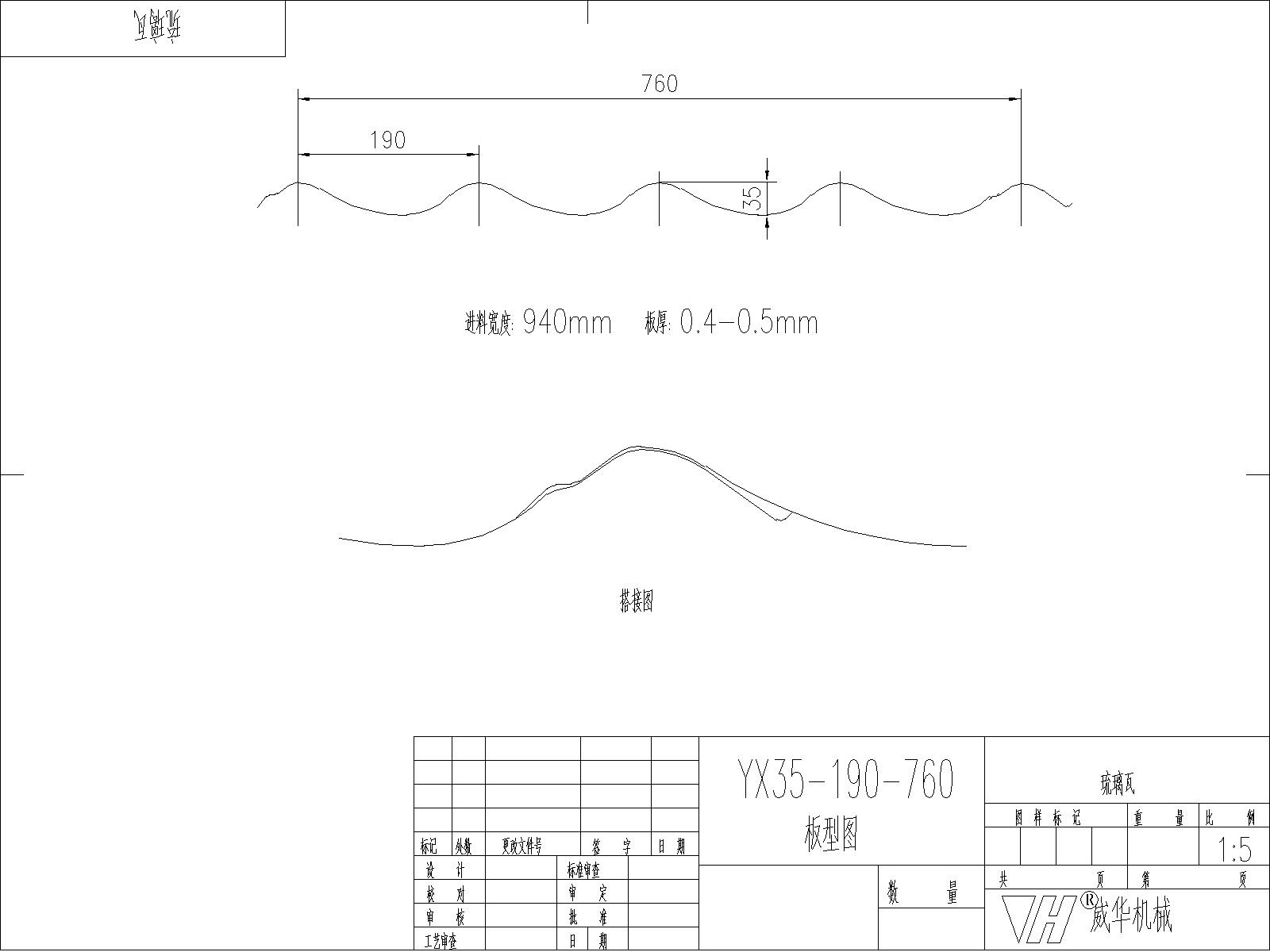

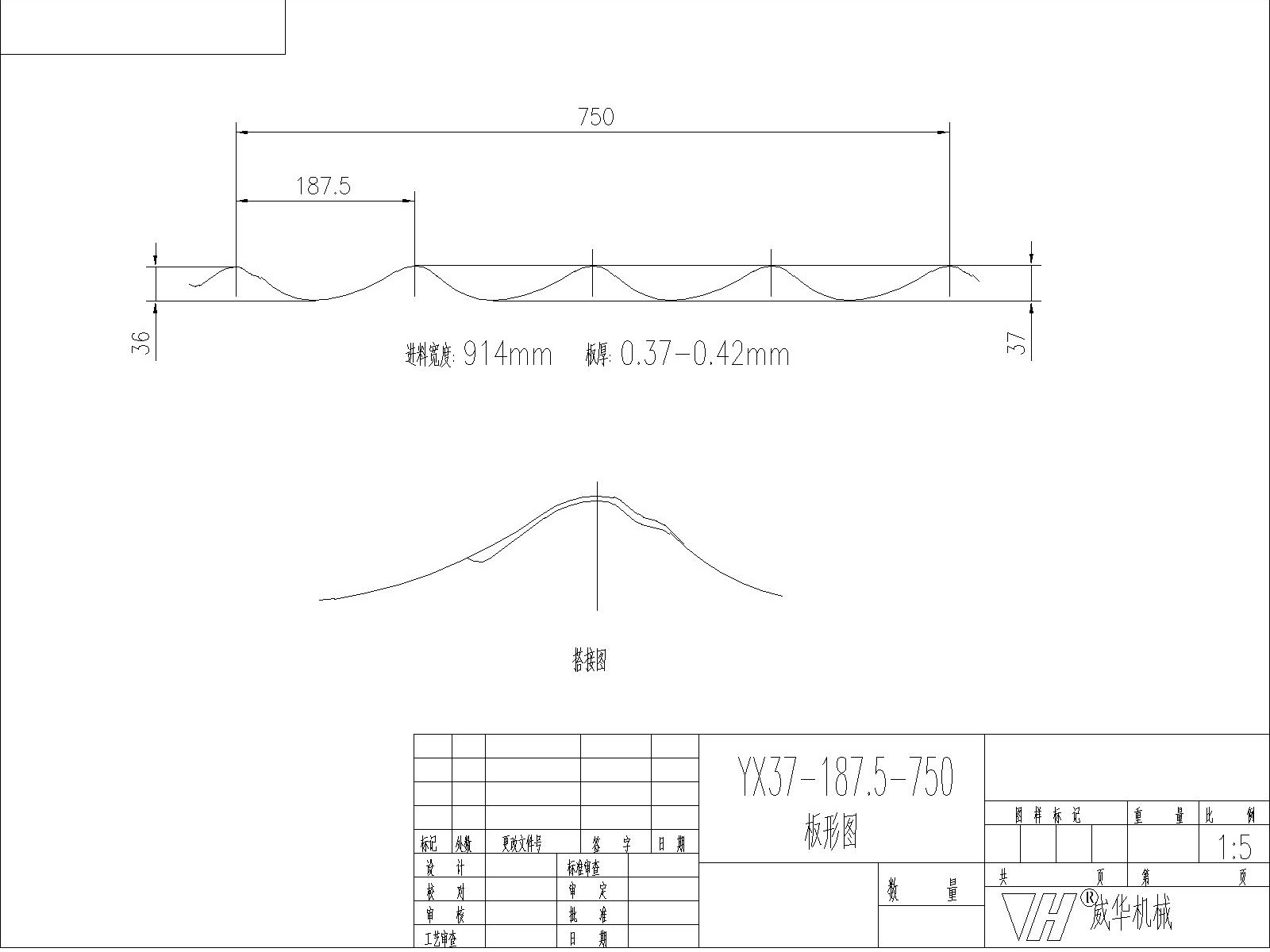

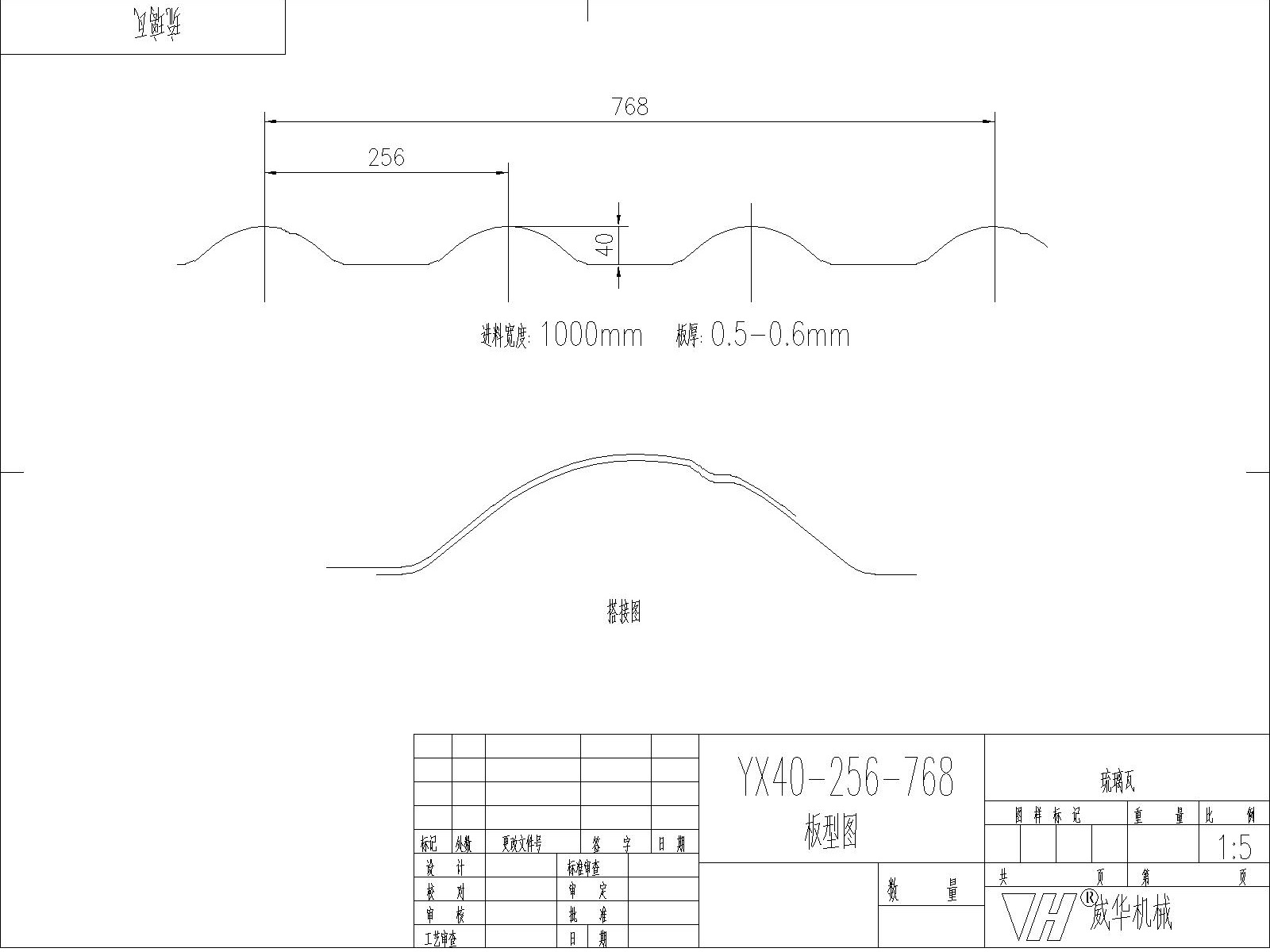

PROFILE

APPLICATION

1.Decoiler:Hydralic decoiler,

2.Weight capability of decoiler: 10T

3.Characteristic of decoiler: hydraulic-umbrella stand,the blocks extend

4.Power of motor of decoiler: 5.5KW

5.Power of hydraulic decoiler expansion: 2.2KW

6.Inner diameter of coil (ID): φ508mm,φ610mm

7.Outer diameter of coil (ID): φ1500mm

8.Width of coil: 1250mm

9.Material of coil: galvanized sheet, color steel sheet

10.Hydraulic pressure of decoil:10MPa

11.Machine stand adopts welded steel structure with shot blasting treatment

12.Locating of movable station:fixed by square key and screw

13.Bearing of fixed station:taper bearing installed in pairs

14.Stand type for guide feeding:side trolley type

15.Type of forming machine:single station with chain transmission

16.Specification of single station: WHPF40

17.Leader: ¢40㎜

18.Diameter of roller shaft:¢80mm(thermal refining)

19.Diameter of bearing assembly hole: ¢60㎜

20.Chain: 16A single row

21.Main motor power:5.5kw

22.Forming speed:1.5m/min(including stamping and cutting step)

23.Roller station:19 stations

24.Material of shaft:45# forging steel(thermal refining)

25.Surface of roller coated with chrome of 0.05mm thickness

26.Motor of hydraulic station:5.5kw

27.Hydraulic oil pump:gear pump CB-E314

28.Type of mould: hydraulic stamping mould

29.Step height of stamping: 15mm

30.Raw material intensity: Q235

31.Material of stam ping mould: 40Cr, with nitrification

32.Cutting: Hydraulic cutting

33.Material of cutter : Cr12

34.Heat treatment of blade: HRC58°-60°

35.Thickness of material:0.5-0.6mm

36.Coil width:1200mm

37.Tolerance of product length:±2mm

38.Type of output table: revolving cylinder(unpowered)

39.Type of transducer:Hongquan, Taiwan

40.Computer adopts PLC,Omron Series

41.Pressure of hydraulic system:12MPa

42.Computer operating board adopts Xinjie OP320A

2.Weight capability of decoiler: 10T

3.Characteristic of decoiler: hydraulic-umbrella stand,the blocks extend

4.Power of motor of decoiler: 5.5KW

5.Power of hydraulic decoiler expansion: 2.2KW

6.Inner diameter of coil (ID): φ508mm,φ610mm

7.Outer diameter of coil (ID): φ1500mm

8.Width of coil: 1250mm

9.Material of coil: galvanized sheet, color steel sheet

10.Hydraulic pressure of decoil:10MPa

11.Machine stand adopts welded steel structure with shot blasting treatment

12.Locating of movable station:fixed by square key and screw

13.Bearing of fixed station:taper bearing installed in pairs

14.Stand type for guide feeding:side trolley type

15.Type of forming machine:single station with chain transmission

16.Specification of single station: WHPF40

17.Leader: ¢40㎜

18.Diameter of roller shaft:¢80mm(thermal refining)

19.Diameter of bearing assembly hole: ¢60㎜

20.Chain: 16A single row

21.Main motor power:5.5kw

22.Forming speed:1.5m/min(including stamping and cutting step)

23.Roller station:19 stations

24.Material of shaft:45# forging steel(thermal refining)

25.Surface of roller coated with chrome of 0.05mm thickness

26.Motor of hydraulic station:5.5kw

27.Hydraulic oil pump:gear pump CB-E314

28.Type of mould: hydraulic stamping mould

29.Step height of stamping: 15mm

30.Raw material intensity: Q235

31.Material of stam ping mould: 40Cr, with nitrification

32.Cutting: Hydraulic cutting

33.Material of cutter : Cr12

34.Heat treatment of blade: HRC58°-60°

35.Thickness of material:0.5-0.6mm

36.Coil width:1200mm

37.Tolerance of product length:±2mm

38.Type of output table: revolving cylinder(unpowered)

39.Type of transducer:Hongquan, Taiwan

40.Computer adopts PLC,Omron Series

41.Pressure of hydraulic system:12MPa

42.Computer operating board adopts Xinjie OP320A

Top