-

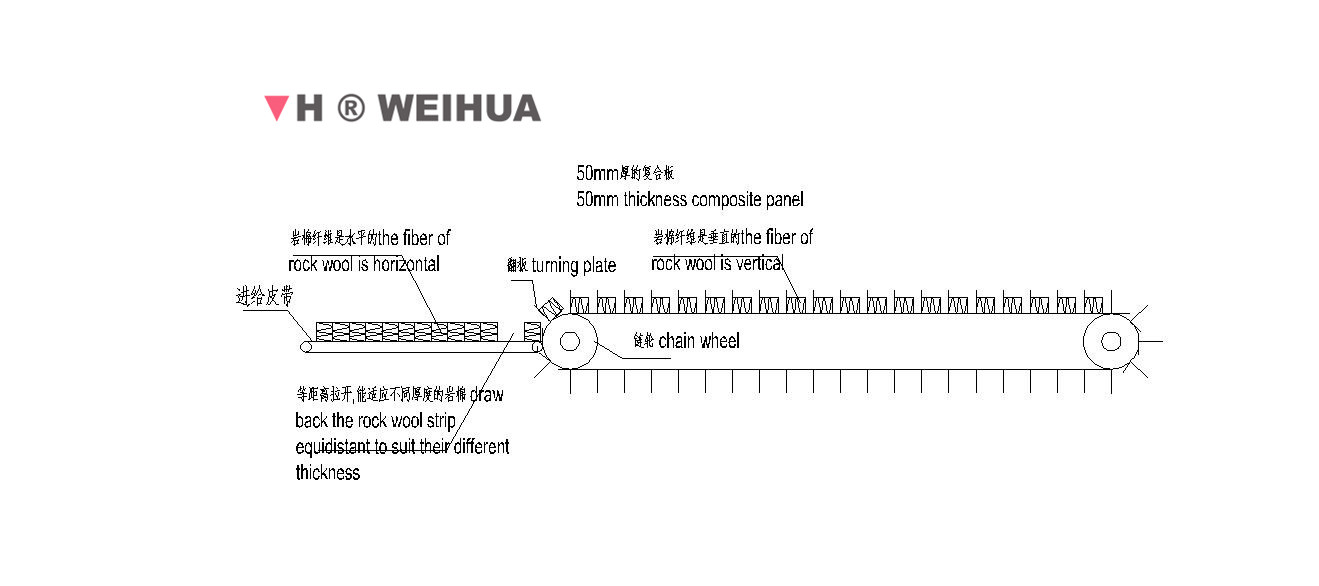

90 degree turning of the rock wool is used for changing the fiber direction and thus increase the adhesion strength of sandwich panel.

-

The cross feed belt conveyor execute pulse feeding, and then enter into the shifting block system, which driven by chain and servo motor. For improving the stability of the shifting block, we adopt a set of active belt for synchronous auxiliary driving. This structure is stable when turning the rock wool, and avoids the instability phenomenon of rock wool free drop turning form that other companies adopt.

Rock Wool 90° Turning

Rock Wool 90° Turning