-

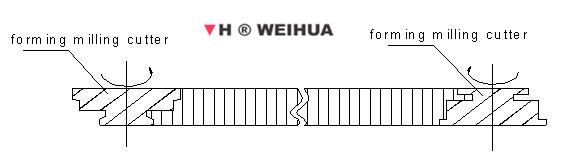

The rock wool edge milling device: milling the rock wool edge to a section which can achieve the requirements of overlap joint.

-

The two sides of the rockwool is milled by the shaping milling blade. We adopt five work station milling to ensure the quality, and it’s also convenient for different joint edge shapes. The milling cutter is installed on the cutter spindle, which is driven by motor. The milling direction is opposite with the conveying of rock wool. The position of milling cutters is set according to the size of the formed steel plate. There is also a cover piece out of cutters, and there is exhaust opening on the cover to protect the cutters.

Rock Wool Edge Milling

Rock Wool Edge Milling